Vehicles with manual transmission

The throttle position sensor should be checked if the engine has poor throttle response, erratic idle, and is not reaching maximum power. The throttle position sensor should also be checked as part of maintenance.

Examination

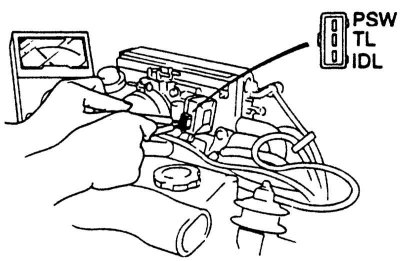

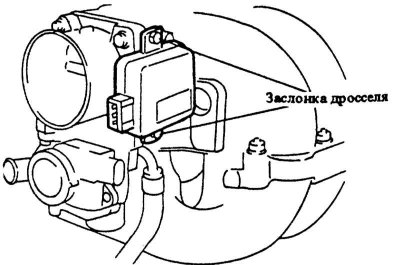

1. Disconnect the plug from the throttle position sensor.

2. Use a feeler gauge to adjust the distance between the throttle stop bolt and the stop lever.

3. Connect an ohmmeter and check the current flow between the terminals.

| Engine | Probe thickness | Between contacts | Current flow | |

| Yes | No | |||

| B6 to 9/89 | 0.5 mm | IDL — TL | X | |

| PSW — TL | X | |||

| 0.7 mm | IDL — TL | X | ||

| PSW — TL | X | |||

| VZ, V6 from 10/89 BP | 0.1 mm | IDL — TL | X | |

| PSW — TL | X | |||

| 1.0 mm | IDL — TL | X | ||

| PSW — TL | X | |||

| All | Throttle valve fully open | IDL — TL | X | |

| PSW — TL | X | |||

4. If the result of one of these measurements does not correspond to the required value, the throttle position sensor should be adjusted.

5. Connect the plug to the sensor.

Adjustment

1. Disconnect the throttle position sensor plug.

2. Connect an ohmmeter between terminals TL and IDL.

3. Adjust the distance between the throttle stop screw and the stop lever to the desired value using a flat feeler gauge.

Required value: before 9/89 issue: 0.5 mm from 10/89: 0.4 mm

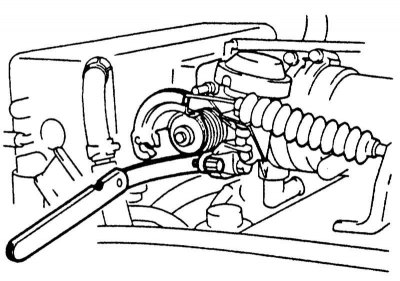

4. Loosen the throttle position sensor mounting bolts.

5. Turn the sensor 30°to the right and then slowly turn it back until the ohmmeter starts to show current flow.

6. Insert a feeler gauge 0.7 mm thick between the throttle stop screw and the stop lever. Now no current should flow at the terminals. If current flows, the adjustment should be repeated.

7. Tighten both mounting bolts with force 2 Nm.

Attention! The throttle position sensor should not rotate when the bolts are tightened.

8. Open the throttle fully several times using the gas pedal.

9. Check throttle sensor adjustment again.