Removing

1. Remove gearbox, see chapter Manual transmission, Chapter Removal and installation of a transmission.

2. Mark the position of the pressure plate on the flywheel with a felt-tip pen or scriber.

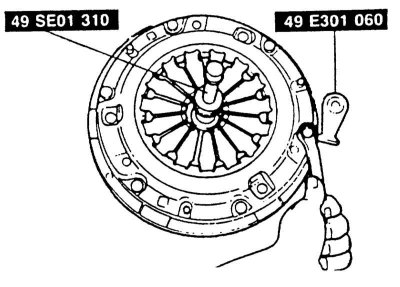

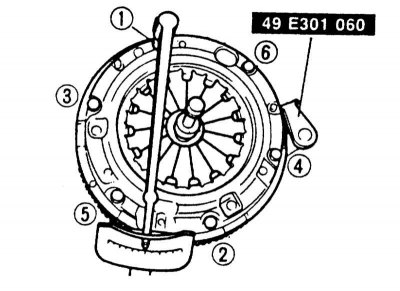

2. To prevent the flywheel from turning when the bolts are loosened, lock it on the ring gear with a screwdriver and a rod. MAZDA workshops use the special tool shown.

3. Alternately loosen the pressure plate mounting bolts by 1-1.5 turns until the pressure plate is unloaded.

Attention! If the bolts are loosened immediately, the diaphragm spring may be damaged.

4. Completely unscrew the bolts.

5. To take out pressure and conducted disks.

Attention! Do not allow the pressure and driven discs to fall when removing, otherwise, after installation, it may be difficult to engage and disengage the clutch.

6. Wipe the flywheel with a rag soaked in gasoline.

Examination

1. Replace oily or mechanically damaged driven discs.

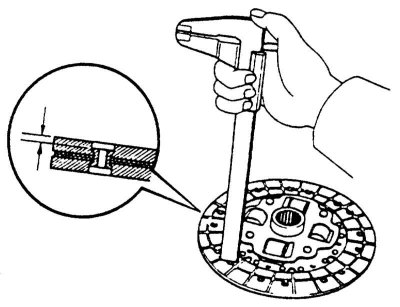

2. Measure the thickness of the driven disc lining using a vernier caliper. The distance to the rivet heads must be at least 0.3 mm, otherwise the driven disk must be replaced. The same is true if there are cracks in the lining.

3. Check the driven disk for runout. Maximum lateral runout of the disc: 0.7 mm. A special tool is required to check, but this is only necessary if an old slave drive is installed that had difficulty turning it on and off.

4. If there were problems with the clutch, check the flywheel lateral runout using a dial gauge. Maximum lateral runout: 0.2 mm.

5. Check the flywheel for traces of soot and grooves, if necessary, grind with fine sandpaper.

6. Check for signs of wear on the release bearing on the diaphragm spring. Smooth out small irregularities with sandpaper, in case of larger damage, replace the pressure plate.

7. Check the spring connections between the pressure plate and the cover for cracks and tightness of the rivets. A clutch with damaged or loose rivets should be replaced.

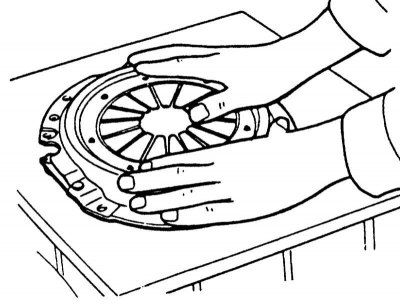

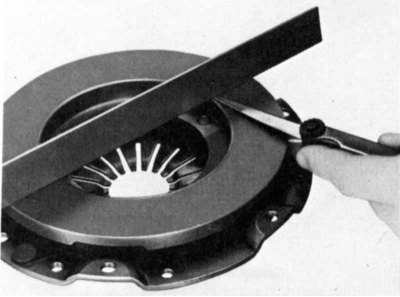

8. Check the contact surface of the pressure plate for cracks, burn marks and wear. Pressure plates with an inward deflection of up to 0.3 mm can still be installed. Checking is carried out using a ruler and a flat probe. If necessary, smooth out burn marks and grooves with fine sandpaper.

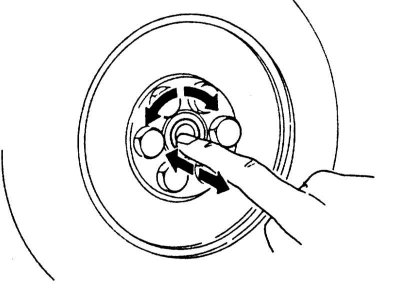

9. Turn the pilot bearing in the flywheel with your finger while pressing on the bearing. Replace the bearing only if it seizes or has free play. A special puller is required for removal. The new bearing is driven in with a hammer and a rod until it is flush with the flywheel.

10. Check the ease of movement of the release bearing.

Installation

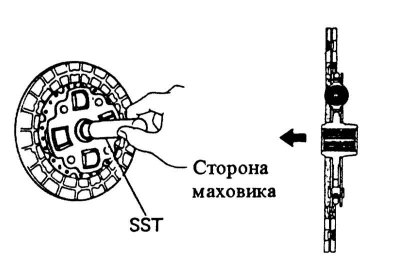

1. Insert the driven plate and pressure plate basket into the flywheel. In this case, the flat side of the driven disk hub faces the flywheel. Approximately align the driven disk to the center in the thrust bearing. However, it is better to center the disc with a suitable rod, such as HAZET or an old gearbox input shaft. If the driven disc is not in the center, the gearbox shaft cannot be inserted.

2. If the old pressure plate is installed, install the basket according to the marking made when removing. In this case, the guide pins on the flywheel will enter the holes in the pressure plate basket.

3. Screw in the basket fastening bolts.

4. Tighten the bolts of the disc basket in the sequence shown in steps of 1 to 1.5 turns until the pressure plate is screwed on. Remove centering rod.

Attention! Make sure that the basket, when tightening the bolts, enters the flywheel evenly and without distortion. Tightening torque of the basket fastening bolts: 25 Nm.

5. Remove the retainer from the clutch.

6. Install gearbox, see chapter Manual transmission.

7. Front-wheel drive petrol models up to MY 8/89 and all station wagon models: Adjust the clutch drive, see Section Clutch pedal/cable adjustment.