Attention! A hot engine can cause serious burns.

Attention! Be careful not to get burned when removing and installing engine components.

Make sure the battery is fully charged.

Warm up the engine to normal operating temperature.

Stop the engine and let it cool for about 10 minutes to cool the exhaust system.

Remove the fuel pump relay.

Remove the air filter assembly.

Remove ignition coils.

Remove all spark plugs.

Measure compression as follows.

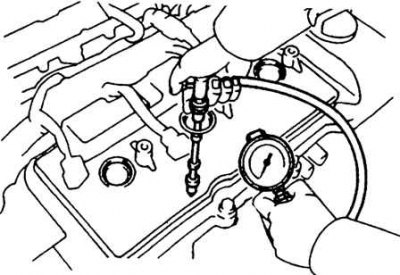

Pic. 2.251. Installing a compression gauge in the spark plug hole

Install a compression gauge in the spark plug hole (pic. 2.251).

Fully open the throttle.

Turn the engine over with the starter and check the compression.

Compression:

- Standard - 1470 kPa (250 min-1);

- Minimum - 1029 kPa (250 min-1);

- The maximum difference between the cylinders is 196.1 kPa.

Perform the first three operations for all cylinders.

If the compression value is less than the minimum value or the compression in one of the cylinders differs from the compression in the other cylinders by 196.1 kPa or more, fill the first three with a small amount of engine oil in the spark plug holes.

If the compression rises after adding engine oil, the piston ring or cylinder surface may be worn or damaged.

If the compression does not rise, then the valves may be stuck, the valves are loose, or the cylinder head gasket is leaking.

In both cases, engine repair is necessary.

Install spark plugs.

Install the ignition coil.

Install the air filter assembly.

Install the fuel pump relay.