Remove the right wheel.

Remove the right mudguard.

Remove spark plugs.

Disconnect the high voltage wire.

Disconnect the oil control valve connector (OCV).

Remove the ventilation hose.

Remove the cylinder head cover. Make sure the engine is cold.

Measure the valve clearance.

To measure the valve clearance, turn the crankshaft clockwise until the #1 piston is at TDC on the compression stroke.

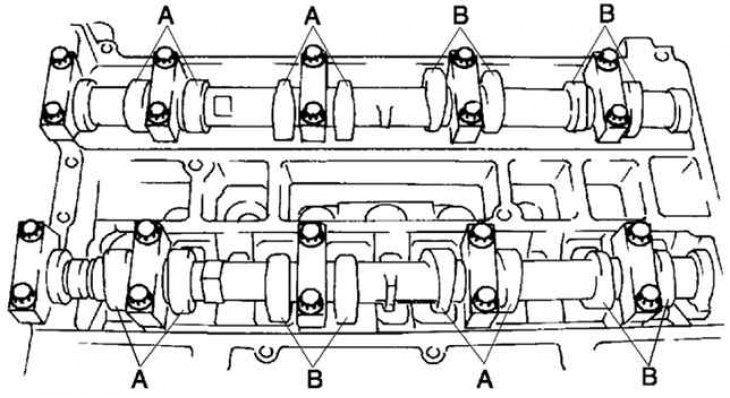

Pic. 2.77. Procedure for measuring valve clearances

Using a feeler gauge, measure the valve clearance at point A (pic. 2.77).

Make a note of the measured values so that you can select the appropriate valve lifters if they need to be replaced later.

Rotate the crankshaft 360°clockwise until the #4 piston is at TDC on the compression stroke.

In the same way as in the first case, measure the valve clearance at point B (see fig. 2.77).

Standard Clearance (on a cold engine):

- inlet - 0.22–0.28 mm;

- release - 0.27–0.33 mm.

If the valve clearances are not correct, adjust them, or, if adjustment is impossible, replace the valve lifters with new ones.

Reinstall all removed parts in the reverse order of removal.