Removing

Remove a transmission in the block with the main transfer.

Remove the clutch release fork cover.

Remove the clutch release fork assembly.

Remove the clutch release bearing clutch.

Remove the clutch release fork support from the transmission.

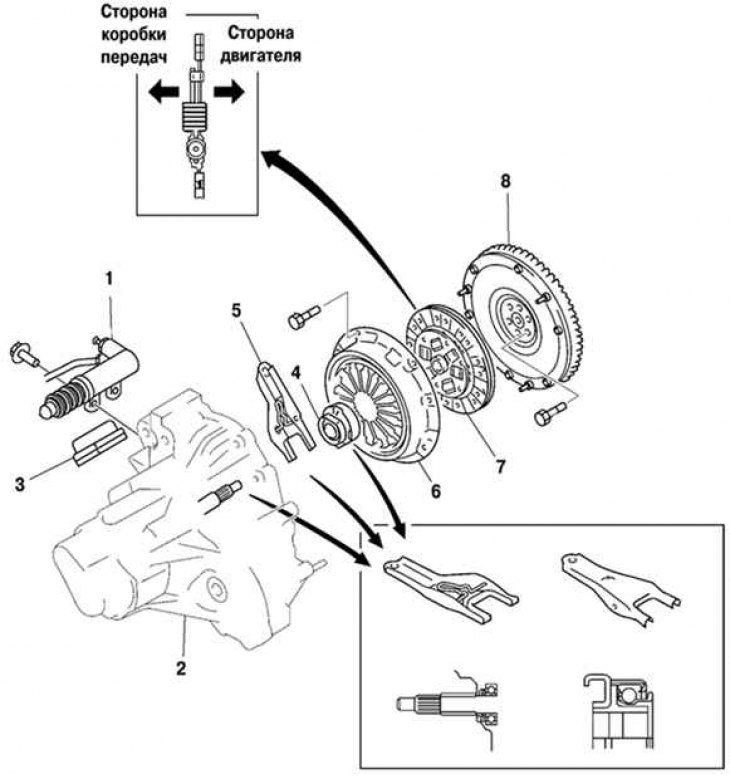

Pic. 3.11. Removing and installing the clutch: 1 – the working cylinder of a drive of deenergizing of coupling; 2 - gearbox; 3 - plug cover; 4 - release bearing; 5 - clutch release fork; 6 - clutch cover; 7 – a conducted disk of coupling; 8 - flywheel

Loosen each bolt at one time, one turn, until the spring force is weakened.

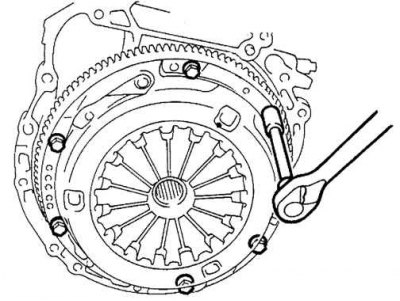

Pic. 3.12. Removing the clutch cover

Remove bolts and clutch cover (pic. 3.12).

Attention! Keep the clutch disc, pressure plate and flywheel surfaces free of oil and foreign objects.

Using the special tool, remove the transmission input shaft support bearing.

Note. Do not remove the transmission input shaft support bearing unless you are replacing it.

Install a special tool to keep the flywheel from turning.

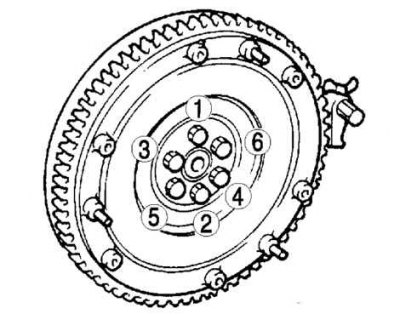

Pic. 3.13. Removing the clutch flywheel

Turn away bolts of fastening of a flywheel in the sequence specified in drawing 3.13.

Examination

Check clutch cover.

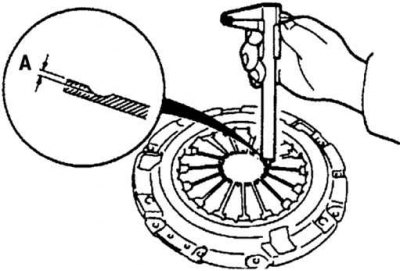

Pic. 3.14. Measuring the wear depth of the diaphragm spring petals

Using a vernier caliper, measure the wear depth of the diaphragm spring petals (pic. 3.14).

Maximum allowable wear in depth A: 0.6 mm.

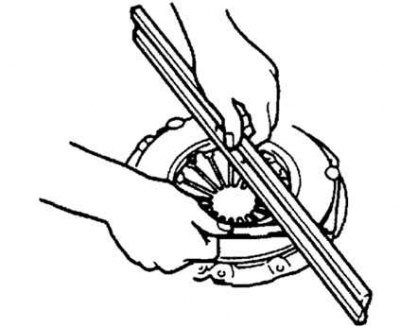

Pic. 3.15. Measuring the gap between the pressure plate and the ruler

Using a ruler and feeler gauge, measure the gap between the pressure plate and the ruler, as shown in Figure 3.15.

Maximum clearance: 0.5mm.

Establish the dial indicator on the block of cylinders.

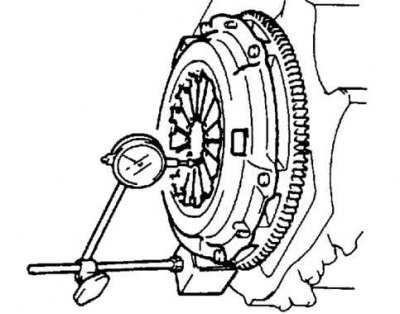

Pic. 3.16. Measuring the deviation of the tops of the petals of the diaphragm spring

Rotating the flywheel, measure the deviation of the tops of the diaphragm spring petals (pic. 3.16).

Maximum deviation from the plane: 0.6 mm.

If one of the measured values is out of specification, replace the clutch cover.

Check the clutch disc.

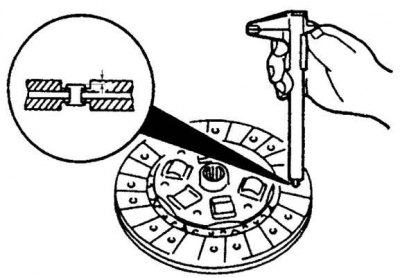

Pic. 3.17. Measuring the friction linings of the clutch disc

Using a vernier caliper, check the thickness of the friction linings on both sides of the release plate in relation to the rivet heads (pic. 3.17).

Minimum lining thickness: 0.3 mm.

If the lining thickness is less than the minimum, replace the disc.

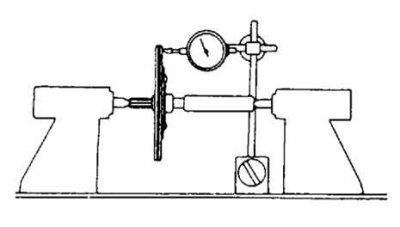

Pic. 3.18. Disc Runout Check

Using a dial indicator, check the axial runout of the disc (pic. 3.18).

Maximum axial runout: 0.7 mm.

If the axial runout exceeds the specified limits, replace the disc.

Pic. 3.19. Checking the release bearing

Applying axial pressure to the release bearing, rotate it (pic. 3.19).

If the bearing is seizing or there is significant resistance to rotation, replace the bearing.

Note. The sealed bearing does not require flushing or lubrication.

Applying thrust to the transmission input shaft support bearing, rotate it.

If the bearing is seizing or there is significant resistance to rotation, replace the bearing.

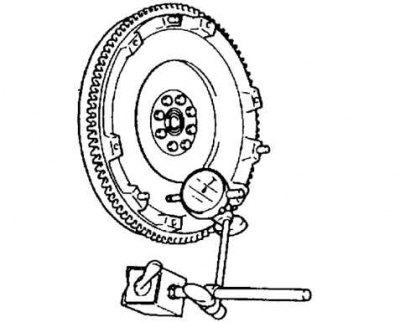

Pic. 3.20. Checking the axial runout of the flywheel

Using a dial gauge, check the flywheel axial runout (pic. 3.20).

Maximum axial runout: 0.2 mm.

If the axial runout exceeds the specified limits, replace the flywheel.

Installation

Install the flywheel on the crankshaft.

When using old bolts, remove the old sealant from the threaded holes for the flywheel bolts in the crankshaft and from the flywheel bolts. Apply sealant to the flywheel mounting bolts and install them.

Note. If installing a new bolt, do not apply sealant to it.

Tighten the flywheel bolts by hand.

Secure the flywheel against turning with the special tool.

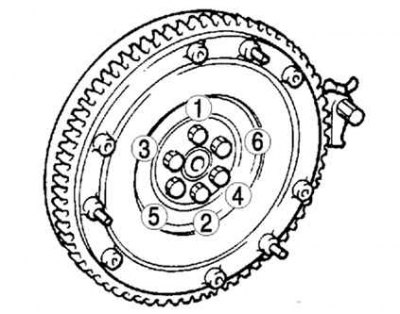

Pic. 3.21. Flywheel tightening procedure

Tighten the mounting bolts in two or three passes in the sequence shown in Figure 3.21.

Tightening torque: 108–115 Nm.

Using the special tool, install a new transmission input shaft support bearing.

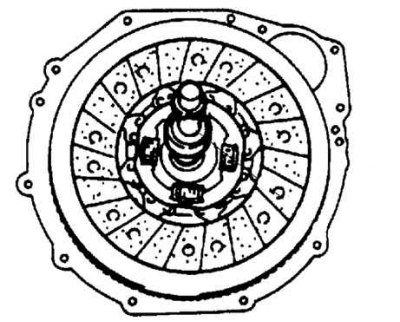

Pic. 3.22. Installing the clutch disc

Install the clutch disc and fix its position with the disc centering tool (3.22).

Install the clutch cover.

Install the special tool.

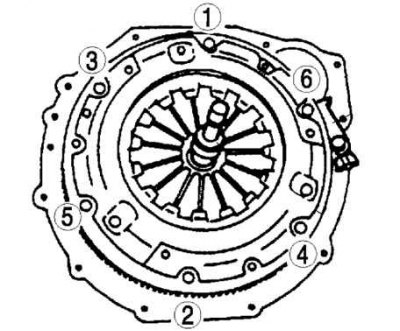

Pic. 3.23. The order of tightening the bolts of the pressure plate

Evenly and gradually tighten the pressure plate mounting bolts in the sequence shown in the figure (pic. 3.23).

Tightening torque: 18.6 - 25.5 Nm.

Install the clutch release fork support to the transmission.

Install the clutch release bearing clutch clip onto the bearing.

Apply grease to the contact surfaces of the clutch and release fork, fork and pushrod, and the fork support point.

Apply grease to the clutch splines and to the drive shaft splines.

Install the clutch release fork with the clutch release bearing into the gearbox.

Note. After installation, move the fork back and forth to check the smooth movement of the release bearing.

Install the clutch release fork cover.

Install the gearbox.