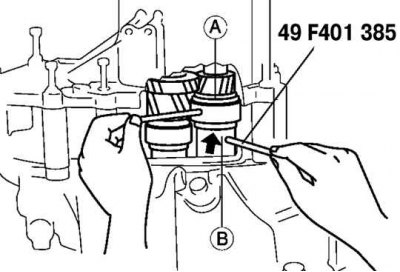

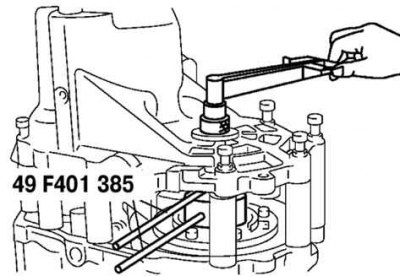

Pic. 3.59. Eliminating gaps before installing bearings

To install bearings, install special tools (rods) into holes A and B of the selectors and turn the selectors so as to increase the clearance. After that, turn the special tool in the opposite direction until the gaps are eliminated (pic. 3.59).

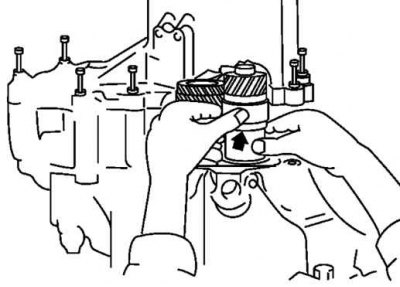

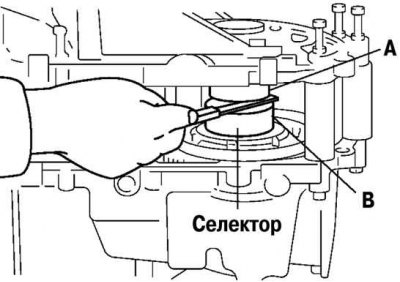

Pic. 3.60. Expanding selectors manually

Manually expand selectors all the way (pic. 3.60).

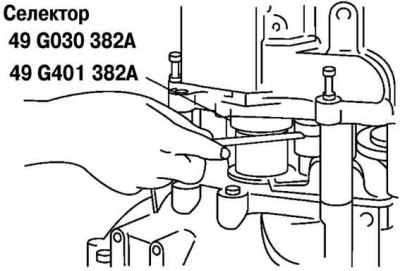

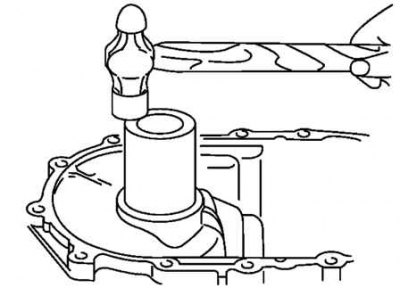

Pic. 3.61. Measuring the gap in the selector

Use a feeler gauge to measure the gap in the special tool (selector) (pic. 3.61).

Attention! Measure the clearance around the entire circumference of the selector.

Attention! Remember the maximum value and select the spacer as follows.

Input Shaft Shim: Select the thinnest allowable shim from the table to obtain standard clearance.

Standard clearance: 0–0.05 mm.

Example:

- probe measurement value - 0.57 mm;

- gasket thickness range: (0.57 mm - 0.05 mm) - (0.57 mm - 0 mm) = 0.52 mm - 0.57 mm;

- gasket: 0.55 mm.

Output Shaft Shim: Select the thinnest acceptable output shaft shim from the table to obtain standard clearance.

Preload: 0.03–0.08 mm.

Example:

- probe measurement value: 0.57 mm;

- gasket thickness range: (0.57mm + 0.03mm) - (0.57 mm + + 0.08 mm) = 0.60 mm - 0.65 mm;

- gasket: 0.60 mm.

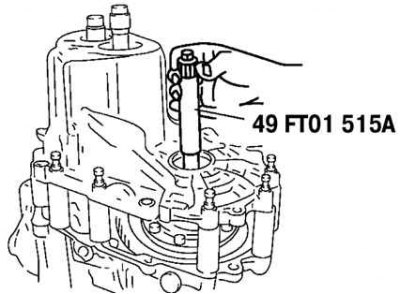

Pic. 3.62. Installing a torque wrench

Install special tool and dynamometer or torque wrench (pic. 3.62).

Pic. 3.63. Selector gap adjustment

Adjust clearance of special tool (selector), to get a specific preload/dynamometer value (pic. 3.63).

Note. Read the preload value when the differential begins to turn.

Note. Measure several times and calculate the average.

- - Preload: 0.5 Nm.

- - Value on the dynamometer: 5 N.

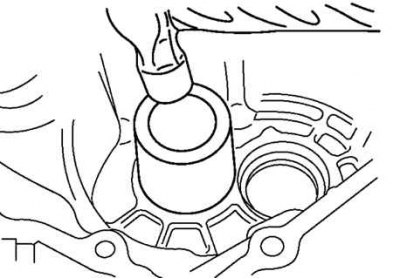

Pic. 3.64. Differential selector clearance measurement

Use a feeler gauge to measure differential selector clearance (pic. 3.64).

Add 0.15mm to the measured gap and select the shim combination that gives the closest fit to the measured value.

Example:

- 0.32 mm + 0.15 mm = 0.47 mm.

- nearest laying (on the thick side): 0.47 mm - 0.50 mm

Remove the final drive housing and special tool.

Remove selectors, input shaft and differential.

Remove the bearing races.

Pic. 3.65. Installing the input shaft bearing race

Install the shim (ki) and input shaft bearing race using a suitable pipe (pic. 3.65).

Attention! Use a shim (ki), selected when adjusting the preload in the bearing.

Pic. 3.66. Installing the differential shaft bearing race

Install the shim (ki) and differential shaft bearing race using a suitable pipe (pic. 3.66).

Attention! Use a shim (ki), selected when adjusting the preload in the bearing.