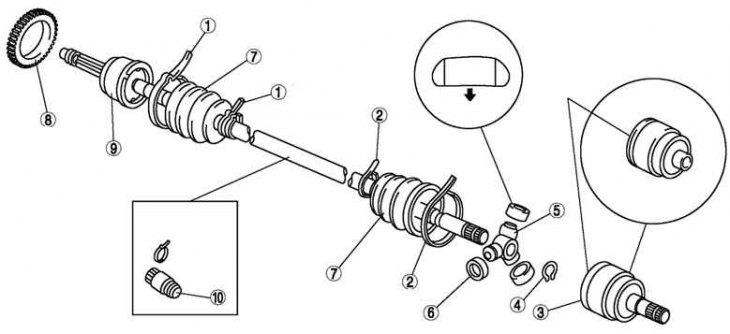

Pic. 3.145. Front Drive Shaft Components: 1 - cover clamp (from the side of the wheel); 2 - cover clamp (from the gearbox side); 3 - hinge body; 4 - retaining ring; 5 - hinge type tripod; 6 - free ring; 7 - case; 8 - the rotor of the sensor of the anti-lock braking system of brakes (with anti-lock brake system); 9 - shaft and ball joint; 10 - dynamic damper

The components of the front drive shaft are shown in fig. 3.145.

Removing

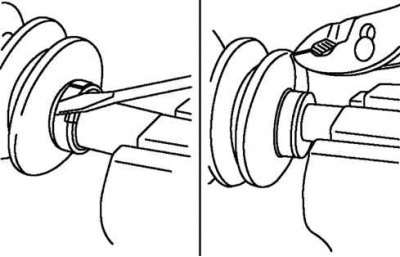

Pic. 3.146. Removing the boot clamp (from the side of the wheel) special pliers

Remove the cover clamp (from the side of the wheel) special pliers, as shown in Figure 3.146.

Bend the locking clips of the clamp with a screwdriver.

Pic. 3.147. Removing the boot clamp (from the gearbox side)

Pull out the end of the clamp (pic. 3.147).

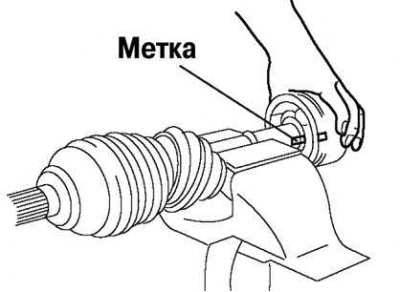

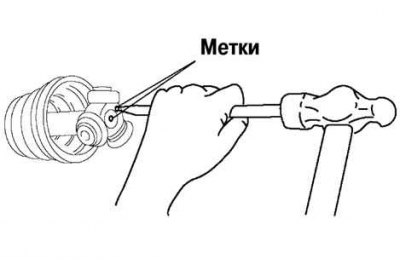

Pic. 3.148. Marking the joint housing and drive shaft

Mark the hinge body and shaft for reassembly (pic. 3.148).

Remove the hinge housing.

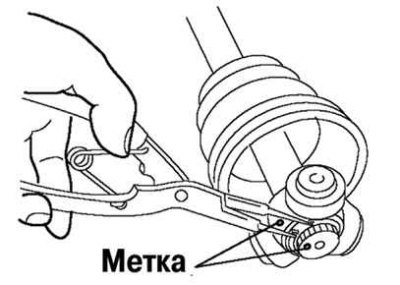

Pic. 3.149. Marking the drive shaft and tripod

Mark the shaft and tripod for reassembly (pic. 3.149).

Remove the circlip using circlip removal and installation pliers.

Remove the tripod connection from the shaft.

Attention! Do not hit the tripod with a hammer.

Note. The wheel side boot must not be removed except when replacing the boot, shaft or ball joint. Do not remove the tape until the cover is assembled.

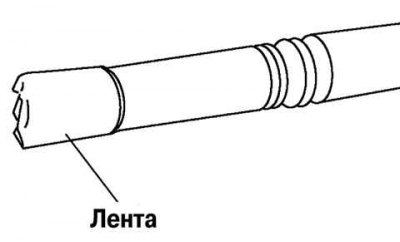

Pic. 3.150. Drive shaft spline protection

Wrap the shaft splines with adhesive tape (pic. 3.150).

Remove the cover.

Note. Do not remove the anti-lock brake sensor rotor (vehicles with anti-lock brakes), if not required. Do not reuse a removed sensor rotor.

Pic. 3.151. Removing the anti-lock brake sensor rotor from the drive shaft

Knock the anti-lock brake sensor rotor off the drive shaft with a chisel (pic. 3.151).

Remove the dynamic damper.

Installation

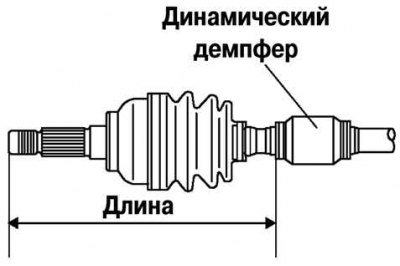

Pic. 3.152. Installing a dynamic damper

Establish a dynamic damper, as shown in Figure 3.152.

Standard length: 334.7 - 340.7 mm.

Install a new boot clamp on the dynamic damper.

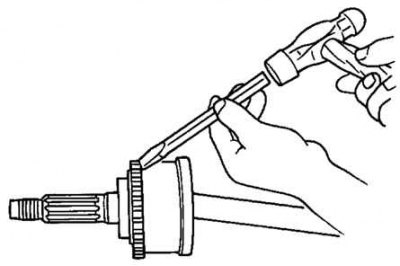

Pic. 3.153. Pressing the new anti-lock brake sensor rotor onto the drive shaft

Install the new anti-lock brake sensor rotor onto the drive shaft and press it in using the special tools (pic. 3.153).

Fill the case (from the side of the wheel) grease.

Note. The covers on the side of the wheel and on the side of the gearbox are different.

Attention! Do not touch the grease with your hands. Apply lubricant from the tube, do not allow contaminants to enter the case.

Attention! Grease quantity: 90-110 g.

Install the cover without removing the adhesive tape that was wrapped around the shaft splines during disassembly.

Remove the tape.

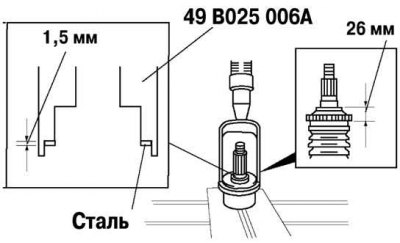

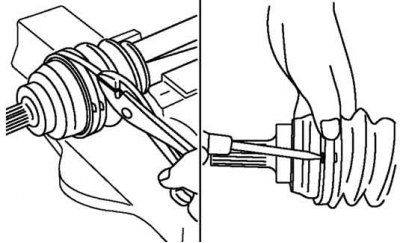

Pic. 3.154. Tripod installation

Align the marks made during removal and install the tripod using a rod and a hammer (pic. 3.154).

Install a new circlip using circlip pliers and circlip pliers.

Attention! Make sure the circlip is seated in the groove of the shaft.

Complete hinge body and case (from the gearbox side) grease.

Grease quantity: 195-215 g

Install the hinge housing.

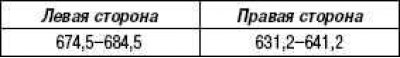

Set the standard drive shaft length.

Pic. 3.155. Removing air from covers with a screwdriver

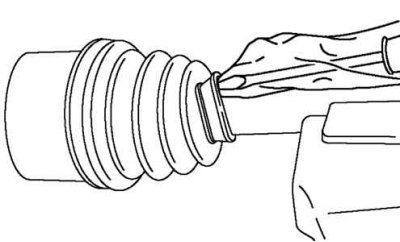

Release the air from the covers by prying up the edges of the smaller ends of the covers with a cloth-wrapped screwdriver (pic. 3.155).

Attention! Avoid leakage of grease. Do not damage covers.

Make sure the drive shaft length is within specification.

Bend the clamp in the opposite direction of the rotation of the drive shaft when the vehicle is moving forward, and using pliers, tighten the clamp firmly.

Pic. 3.156. Installing the boot strap (from the gearbox side)

Block the end of the clamp by bending the locking clips (pic. 3.156).

Attention! Install the clamp securely into the groove.

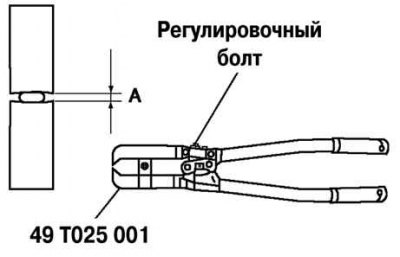

Adjust clearance A

Pic. 3.157. Gap adjustment A of the boot (from the side of the wheel)

by turning the adjusting bolt of the special tool (pic. 3.157).

Gap A: 2.9 mm.

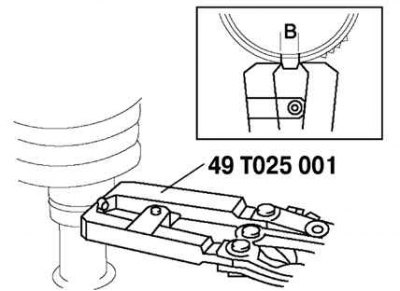

Compress the small clamp on the wheel side of the boot using the tool. Check that the gap IN

Pic. 3.158. Gap adjustment in boot (from the side of the wheel)

- within the normal range (pic. 3.158).

If the gap IN greater than normal, reduce the clearance of the special tool and re-compress the boot.

If the gap IN less than normal, replace boot clamp, increase special tool clearance, and compress new boot.

Gap IN: 2.4–2.8 mm.

Make sure that the boot strap does not protrude from the boot strap installation area.

If so, replace boot strap and reinstall.

Fill the case with grease from the repair kit.

Adjust clearance IN by turning the adjusting bolt of the special tool.

Gap IN: 3.2 mm.

Make sure that the boot strap does not protrude from the installation area.