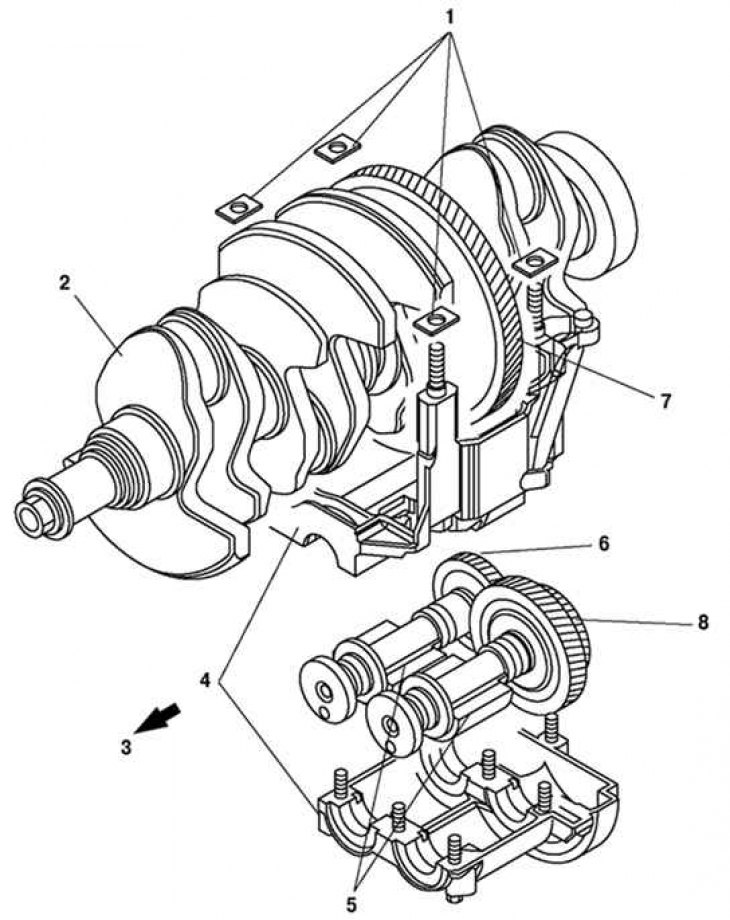

Pic. 2.12. The principle of operation of the balancing unit: 1 - adjusting gasket; 2 - crankshaft; 3 - the front of the engine; 4 - body of the balancing block; 5 - counterweights; 6 - balancing shaft No. 2; 7 - drive gear; 8 - balancing shaft No. 1 with a driven gear

Structurally, the balancing block is installed under the crankshaft, has two balancing shafts and a body-bed in which they are placed. With the help of balancing shafts and shims, the clearance in engagement with the crankshaft is adjusted. Balance shafts (No. 1 and No. 2) driven by the crankshaft drive gear. The rotational movement is transmitted from the drive gear, which is located between the main journals of the third and fourth cylinders, directly to the balance shaft No. 1 with the driven gear. The balancing block transmits rotation to the balancing shaft No. 2. The ratio of the gears of the balancing shafts was chosen so that the gear rotates twice as fast as the crankshaft. The speed of rotation of the balancing shaft balances the force of inertia of rotation (secondary inertial force of rotation) crankshaft. The balancing block is not disassembled and not repaired (pic. 2.12).

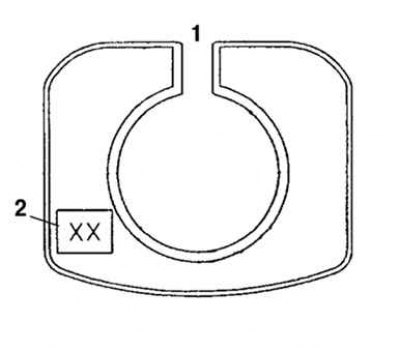

Pic. 2.13. Marking of shims of the balancing block: 1 – block of cylinders; 2 - identification label (2 digits)

Note. To adjust the gap between the balancing block and the crankshaft, replace the shim. There are 40 types of gaskets of various thicknesses. To determine the type of gasket, find the marking (2 digits) on gasket (pic. 2.13).