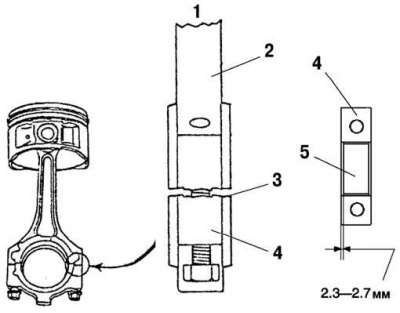

Pic. 2.18. Connecting rod and connecting rod bearing: 1 - expansion; 2 - connecting rod; 3 – parting surface; 4 - connecting rod cover; 5 - connecting rod bearing

The connecting rod is made of structured hardened alloy for improved rigidity. The conventional connecting rod bearing dowel is not used. When installing the bearing, measure the position of the bearing and install it so that it is centered on the connecting rod and the connecting rod bearing cap. The bottom head and connecting rod cap are formed as a single piece during manufacture, and then separated into a connecting rod and cap. Use the parting surface configuration to align the connecting rod and cap. The connecting rod bolt has a tightening torque in the plastic zone, tightening is carried out in two steps. The upper shell of the connecting rod bearing is made of aluminum alloy (pic. 2.18).

Note. There are three types of connecting rod bearing shells depending on the required clearance.

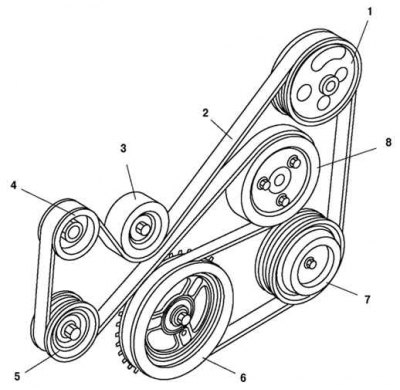

Pic. 2.19. Accessory drive belt outline: 1 – a pulley of the hydraulic booster pump; 2 - drive belt; 3 - tension pulley; 4 - generator pulley; 5 - automatic tensioner; 6 - crankshaft pulley; 7 – a pulley of the compressor of an air conditioning system; 8 – a pulley of the pump of a cooling liquid

The accessory drive system uses one V-ribbed drive belt. This shortens the length of the motor and makes circuit maintenance easier. To tension the belt, an automatic tensioner with a coil spring is used. Tensioner pulley automatically maintains drive belt tension (2.19).

Table 2.4. Types of connecting rod bearing shells (mm)

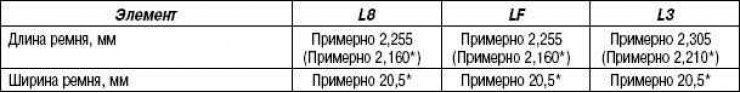

Table 2.5. Drive belt specifications

* vehicles without air conditioning