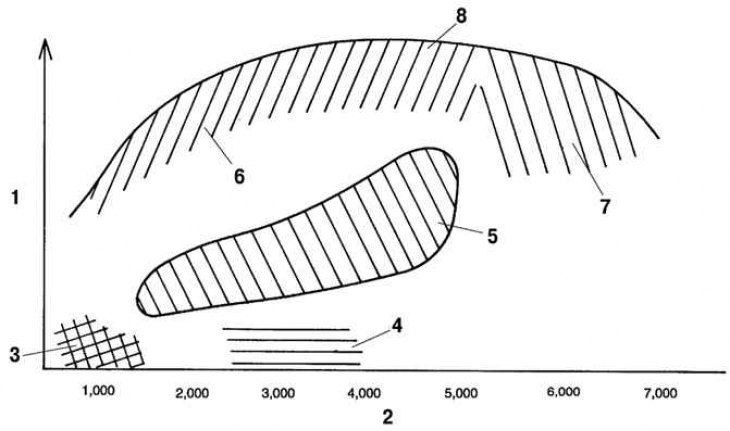

Work according to driving conditions: idling, light loads

By reducing the overlap, less combustion products are returned to the cylinder. This stabilizes the idling speed, improving fuel economy, and also guarantees the stability of the engine at light loads.

Pic. 2.30. Diagram of changes in valve timing for different ranges of engine operation: 1 - load; 2 - engine speed; 3 - idle range; 4 - range of small loads; 5 - range of average loads; 6 - range of large loads of low and medium speeds; 7 - range of large loads and high speeds; 8 - work at full load

Medium loads

The overlap increases and the EGR ratio in the cylinder increases. This reduces friction losses (pumping losses), the combustion temperature decreases and the amount of CO in the exhaust gases decreases. The amount of hydrocarbon emissions is also reduced due to the re-burning of the non-ignited gas.

Heavy load, low and medium speeds

The intake valves close early, resulting in high volumetric efficiency while improving torque in the low to medium speed range.

Heavy load, high speed range

Intake valves close later, high volumetric efficiency ensures maximum power.

At low temperature

The overlap is minimized to prevent combustion products from entering the cylinders and to reduce the amount of additional fuel injected into the cylinders. This improves fuel economy and stabilizes high idle speeds.

When starting or stopping the engine

Starting performance is improved due to reduced overlap, as combustion products are not returned to the cylinder.

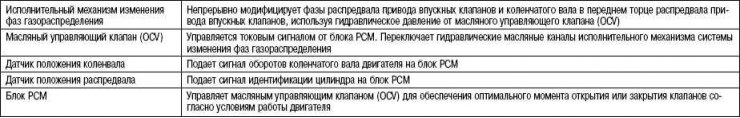

Table 2.12. Elements and their functions