Note. Measurement of compression in the engine cylinders is recommended in the following cases: reduced engine power, increased consumption of engine oil, increased fuel consumption.

Warm up the engine to normal operating temperature, stop it and wait 10 minutes.

Remove the spark plug coils.

Remove all spark plugs from cylinder heads.

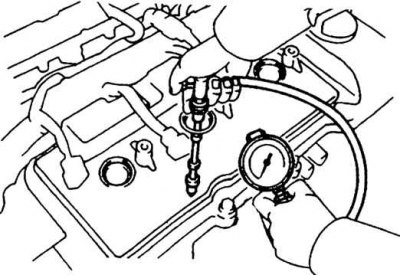

Pic. 2.73. Installation of compression gauges

Insert the tip of a compression tester into the spark plug hole of the cylinder head and measure the compression in the engine cylinders (pic. 2.73).

Fully open the throttle.

Take readings of the compression gauge while cranking the engine with the starter.

Note. When measuring compression, the battery must be fully charged, since for a correct measurement it is necessary that the engine speed be at least 300 min-1.

Repeat the measuring operation for each cylinder.

Note. The duration of the compression measurement in each cylinder should be as short as possible.

Compression value for L8 engines:

- standard - 1750 kPa (17.855 kg/cm2);

- minimum allowable - 1225 kPa (12.492 kg/cm2).

Difference in measured compression values across engine cylinders (for a good engine) should be no more than 196.1 kPa (1.99 kg/cm2).

Compression value for LF model engines:

- standard - 1720 kPa (17.539 kg/cm2);

- minimum allowable - 1204 kPa (12.277kg/cm2).

Difference in measured compression values across engine cylinders (for a good engine) should be no more than 196.1 kPa (1.99 kg/cm2).

Compression value for L3 engines:

- standard - 1430 kPa (14.581 kg/cm2);

- minimum allowable - 1000 kPa (10.197kg/cm2).

Difference in measured compression values across engine cylinders (for a good engine) should be no more than 196.1 kPa (1.99 kg/cm2).

If the compression in one or more cylinders is below the minimum allowable value, pour a small amount of engine oil into the cylinder through the spark plug hole and re-measure the compression in this cylinder.

If, after the oil has been filled into the cylinder, the compression value has increased, then most likely there is wear or damage to the piston rings or cylinder walls.

If, after the oil was poured into the cylinder, the compression did not change, then most likely there is a stuck valve or a loose fit in the seat, or a leak through the cylinder head gasket.

Install the spark plugs.

Install the spark plug coils.