Remove the oil pan.

Remove the oil filter.

Remove the oil cooler.

Remove the knock sensor.

Remove the oil separator.

Remove the thermostat.

Remove the coolant pump.

Remove the mesh oil filter.

Remove the oil pump.

Remove the flywheel (models with manual transmission). To remove the drive disc (models with automatic transmission):

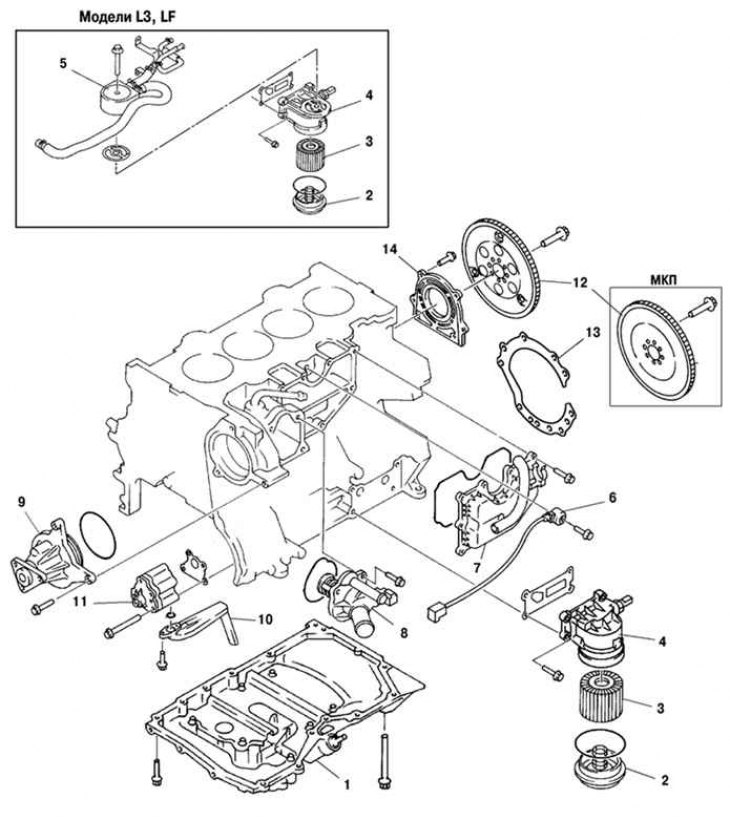

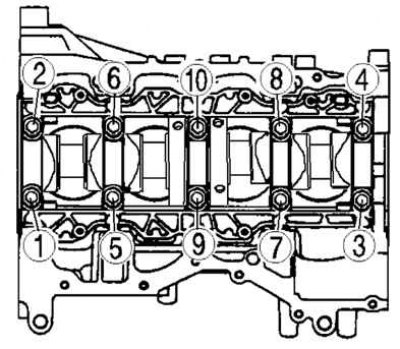

Pic. 2.127. Components of the first stage of disassembly of the cylinder block: 1 - oil pan; 2 - oil filter cover; 3 - oil filter; 4 - oil filter adapter; 5 – oil cooler; 6 - knock sensor; 7 - oil separator; 8 - thermostat; 9 - coolant pump; 10 - mesh oil filter; 11 - oil pump; 12 - flywheel (model with manual transmission), drive disk (models with automatic transmission); 13 - end disk (model with manual transmission); 14 - rear oil seal

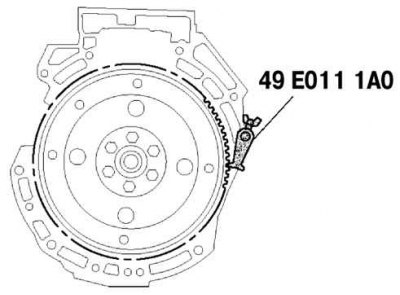

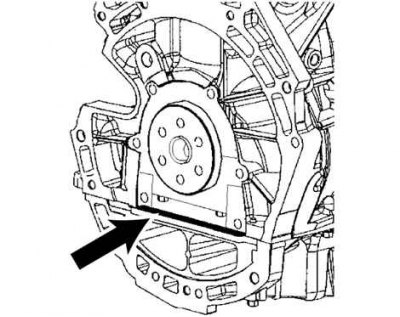

Pic. 2.128. Holding the crankshaft from turning with a special tool

- hold the crankshaft from turning with a special tool (pic. 2.128);

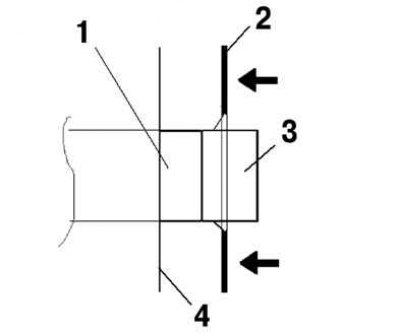

Pic. 2.129. Components of the drive disk and the order of unscrewing the mounting bolts: 1 - bolt; 2 - adapter; 3 - leading disk

- turn away bolts for some receptions in the order specified in drawing 2.129.

Remove the end disc (models with manual transmission).

Remove the rear seal.

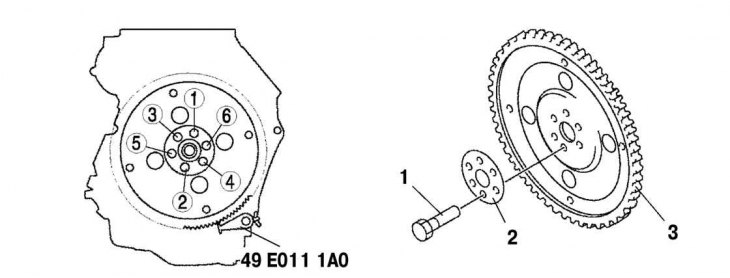

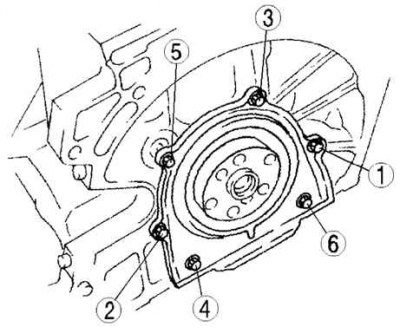

Pic. 2.130. Removing the rear crankshaft oil seal: 1 - bolts; 2 - stuffing box

Unscrew the six bolts securing the rear oil seal and remove the oil seal (pic. 2.130).

Pic. 2.131. Sealing locations

Apply organosilicon sealant to mating surfaces at the location shown in Figure 2.131. Application point diameter 0.4–0.6 mm.

Apply clean engine oil to the lip of the new oil seal.

Pic. 2.132. Installation diagram of the crankshaft rear oil seal: 1 - crankshaft; 2 – a back epiploon; 3 - fixture for installation; 4 - block of cylinders

Establish and press in a back epiploon, using the adaptation for installation of a detail, as is shown in drawing 2.132.

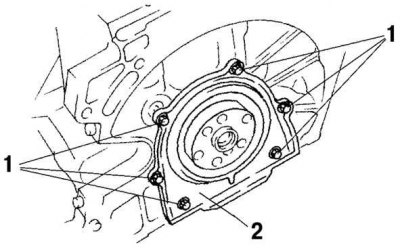

Pic. 2.133. The order of tightening the bolts of the rear crankshaft oil seal

Tighten bolts of fastening of a back epiploon in the order specified in drawing 2.133, the moment of an inhaling of 8,0–11,5 Н·м.

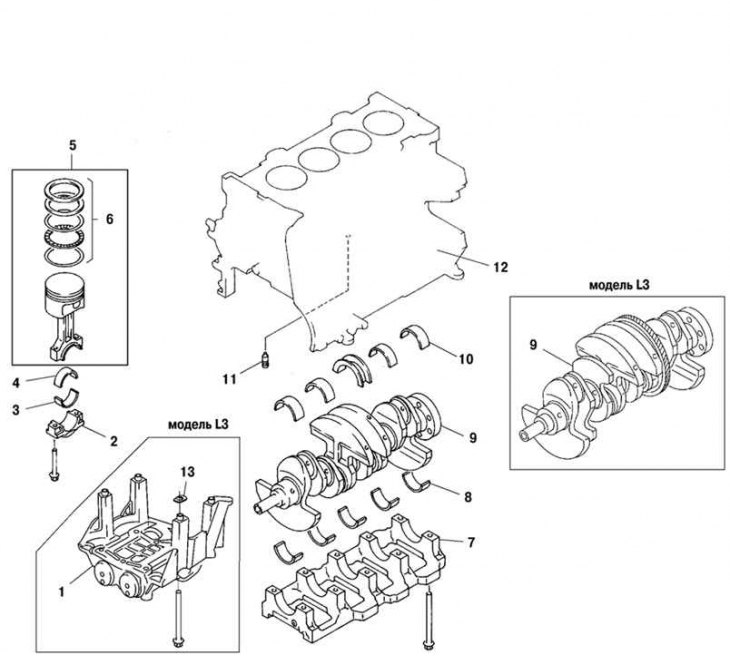

Pic. 2.134. Components of the second stage of disassembly of the cylinder block: 1 - balancing block (L3, L3 with variable valve timing); 2 – connecting rod cover; 3 - lower connecting rod bearing; 4 - upper connecting rod bearing; 5 - connecting rod and piston assembly; 6 - piston ring; 7 – a cover of the radical bearing; 8 - lower main bearing, thrust bearing; 9 - crankshaft; 10 - upper main bearing, thrust bearing; 11 - oil spray nozzle valve; 12 – block of cylinders; 13 - adjusting gasket

Remove the balancing block (engines L3, L3 with variable valve timing, see fig. 2.134).

Remove the connecting rod cover. Before removing the connecting rod cap, check the end clearance of the connecting rod (see below). Remove the connecting rod bolt from the connecting rod cap by hitting the bolt with a nylon hammer.

Remove the lower connecting rod bearing.

Remove the upper connecting rod bearing.

Remove the connecting rod and piston assembly.

Remove piston rings.

Pic. 2.135. The procedure for loosening the bolts of the main bearing cap

Before removing the main bearing cap, check the crankshaft end play. Loosen the cap bolts of the main bearings in two or three stages in the order shown in Figure 2.135.

Remove the lower main and thrust bearings.

Remove the crankshaft.

Remove upper main bearings, thrust bearings.

Remove the oil spray nozzle valve.