Examination

Mark the position of the front wheels on the hubs, so that you can then install the wheels in their original positions. Loosen the wheel nuts with the vehicle on the ground. Raise and support the vehicle at the front and remove the front wheels.

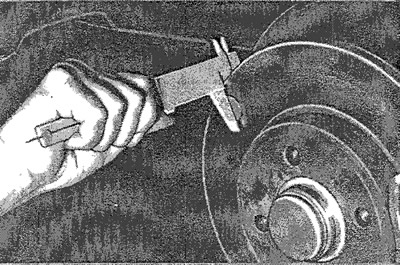

Measure the brake disc thickness. In workshops, a special caliper or micrometer of a special shape is used for this, because. due to wear of the disk, a shoulder forms on it.

|  |

You can measure the thickness of the brake disc with a conventional caliper, but you need to put a coin under both of its lips, the total thickness of which is taken into account when processing the measurement results.

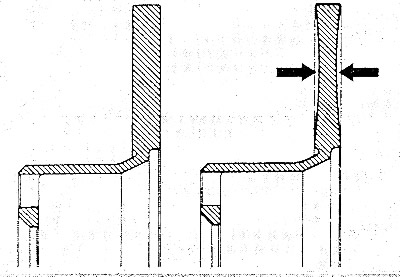

Attention: The measurement must be carried out at several points along the circumference of the brake disc.

Attention: Always measure the disc thickness at the thinnest point (arrows).

The dimensions of the brake discs are in the table at the beginning of the chapter.

If the wear limit is reached, replace the brake disc.

For severe scratches and gouges (deeper than 0.5 mm) replace brake discs.

Note: The brake disc runout can be measured in a workshop. Lateral runout should not exceed 0.1 mm. The measurement is made in the middle of the working surface of the disk.

Install the front wheels in accordance with the marks made earlier, after lightly lubricating the centering holes of the disc with grease. Do not lubricate the threads of the wheel studs. Tighten the wheel nuts. Lower the vehicle and tighten the wheel nuts crosswise to 90 Nm.