Note: If only the brake disc is to be removed, the brake line does not need to be unscrewed from the caliper. In this case, you need to hang the caliper on the body with a wire so that the hose is not stretched and twisted.

Removing

Caution: Release any pressure that may be present in the brake system. To do this, press the brake pedal at least 20 times.

Mark the position of the front wheels relative to the hubs, so that you can then install the wheels in their original positions. Loosen the wheel nuts with the vehicle on the ground. Raise and support the vehicle at the front and remove the front wheels.

If necessary, unhook the brake hose from the steering knuckle.

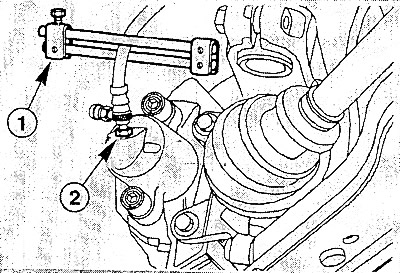

Clamp the brake hose with a suitable clamp.

If the brake caliper is to be completely removed: Loosen the connecting bolt (2) brake hose on the caliper without unscrewing it.

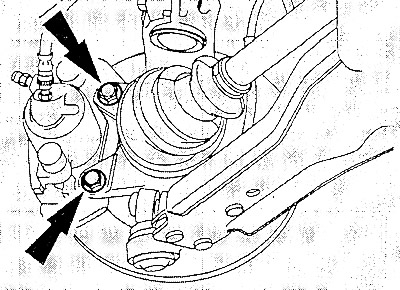

Unscrew the bolts securing the caliper with the bracket from the steering knuckle.

Remove the caliper from the brake disc.

If only the brake disc is removed: hang the caliper on the wire hook on the body so that the brake hose is not twisted or under tension.

Attention: Do not unscrew the brake hose, because after installation, you will have to remove air from the brake system.

If the caliper is removed completely: turn the caliper several times, unscrewing it from the brake hose. If necessary, hold the brake hose at the hexagon with an open end wrench.

Precautions: when opening the brake circuit, some brake fluid will flow out. It must be collected in a container. You can also suck the brake fluid out of the reservoir.

Pull the mounting bracket off the threaded studs and remove the brake disc.

Caution: The brake disc must not be separated from the wheel hub by hammer blows. Instead, use a suitable rust dissolver to avoid damaging the brake disc. If removal is only possible with hammer blows, the brake discs and wheel bearings must be replaced for safety reasons. Wheel bearings must be replaced by a workshop, as this usually requires a special press. Replace brake discs even after using pullers.

Installation

To achieve uniform braking on both sides of the vehicle, both brake discs must have the same thickness and wear patterns. Therefore, it is imperative to replace both brake discs.

In the workshop, you can check the discs for runout and for uniform thickness. Technical data are shown in the table.

Measure the brake disc thickness.

If present, remove rust from brake disc flange and hub.

Remove protective varnish from new brake discs with solvent.

Install brake disc and secure with bracket.

If unscrewed, screw the brake caliper onto the brake hose.

Install brake caliper with pads. Do not kink or stretch the brake hose while doing this.

Fasten the caliper together with its bracket with two bolts, tightening the bolts to a torque of 60 Nm.

If the brake hose has been removed, tighten the brake hose connecting bolt on the caliper to 15 Nm, remove the clip from the brake hose and bleed the brake system.

Install the front wheels in accordance with the marks made earlier, after lubricating the centering hole of the disc with grease. Do not lubricate the threads of the wheel studs. Tighten the wheel nuts. Lower the vehicle and tighten the wheel nuts crosswise to 90 Nm.

Caution: With the vehicle stationary, depress the brake pedal several times until a strong resistance is felt.

Conduct a security check.

Security check

Are the brake lines tight?

Is the brake hose in the mount?

Are the bleed valves tight?

Is there enough brake fluid?

Carry out a density test with the engine running. To do this, press the brake pedal with a force of 200-300 N (20-30 kg) for 10 seconds. The pedal must not fall. Check the tightness of all connections.

Carefully run in new brake discs, for which, on a road with little traffic, brake the car several times from 80 to 40 km / h, gently pressing the pedal. Let the brakes cool down between braking.