Examination

Check tire pressure and correct it. O Take a test drive. If possible, determine the conditions for the appearance of vibration more precisely: speed range, nature of the road, driving in a straight line or in a turn.

Raise and support the vehicle.

Check centering of disc centers. In this case, the hub or brake drum must evenly adjoin the discs. Replace disk if necessary.

Check the wheel suspension, why inspect the rubber-metal bearings (silent blocks), ball joints, shock absorbers and discs, check their condition.

Remove and clean the wheels, remove foreign objects from the tread pattern.

Check the tires on the brake stand, as when braking with locked wheels, sections of the profile with a reduced height of the pattern may occur.

Check the tread depth of the individual tires and compare the values. If the front and/or rear tires show abnormal wear, the wheel alignment must be measured and adjusted if necessary. In this case, the toe adjustment must be made for the upper allowable value.

Attention: Measurements require complex instruments, which are usually only available in workshops.

Carry out a test drive and check if the faults persist.

Checking lateral runout and runout in height

With the vehicle raised, place the dial indicator on the work surface (tread), and then onto the sidewall of the tire. Slowly turn the wheel by hand, check the readings of the dial indicator and mark with chalk the place of maximum runout in height on the tire. Setting value: maximum vertical runout - 0.8 mm, maximum lateral runout - 1.2 mm.

If these values are not reached, balance the wheels on a wheel balancer. In this case, the wheels must be centered as they are on the car. Tapered jigs that center the wheel in the middle hole are not allowed. Permissible residual imbalance in both planes is 5 grams.

Eliminate lateral runout

Release the air from the tire and press the lug of the tire into the rim.

Rotate the tire on the rim by 120°.

Inflate the wheel and recheck the runout.

If the maximum runout value is exceeded, rotate the tire on the rim an additional 120°and check the runout again.

If the runout value is within the maximum value, balance the wheel.

Check for runout in height and lateral runout of the disc

Center the rim without tire on the wheel balancer or on the car. Install dial gauge.

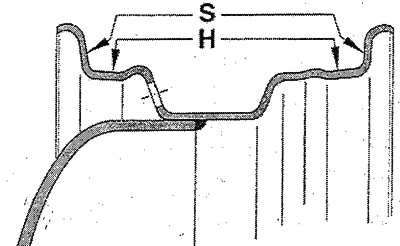

Measure the vertical runout and lateral runout of the disc. Elevation runout (disc shape deviation from circumference) is measured on the disc flange, and lateral runout is measured on the side surface of the rim flange. In this case, it is not necessary to pay attention to jumps in the indicator needle caused by protrusions or indentations of the disc material. (S - places of measurements of lateral runout; H - places of measurements of beating in height). Maximum runout in height - 0.5 mm; maximum lateral runout - 0.8 mm.

If the maximum values are exceeded, then replace the disk.

Installing wheels on a car

With the car raised, set the wheels so that the place of maximum runout in height is at the top. Tighten wheel bolts crosswise with a torque wrench to 140 Nm.

Attention: When the difference in wear between the individual wheels is small, the wheels with the least run-out in height and with the smallest balance weights should be installed on the front axle.

Take a test drive. If there is still vibration in the front of the body or in the steering wheel, then this may be due to a residual imbalance that can be corrected by balancing on the vehicle.

Wheel balancing on a car

When balancing the drive wheels, be sure to install both tires of the same axle on the rollers.

The wheels must be driven by the vehicle's engine so that the wheels rotate synchronously.

Take a control trip.

If there are still imperfections, then this means that there is too much radial runout or runout due to misalignment on one or more wheels. It is impossible to check even in the workshop. In this case, it remains to replace the front and / or rear tires (tires must be replaced in pairs).