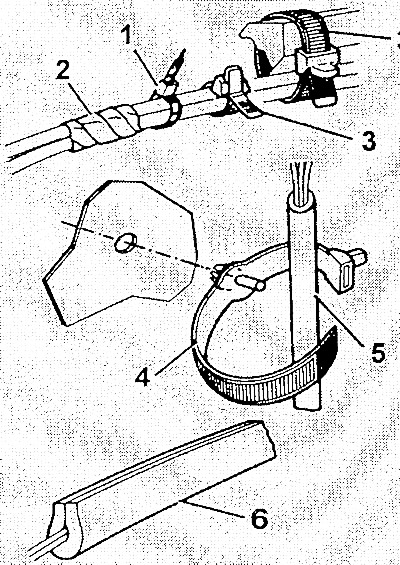

1. Band clamp; 2. Insulating tape; 3. Fastening tape; 4. Ribbon (collar) fastenings with fastening in a hole; 5. Protective tube (cambric); 6. Self-adhesive foam tape.

The wire, which, when installing additional equipment, is laid in addition to the wires already existing in the vehicle, should, if possible, always be routed along the existing wiring harnesses using the existing clamps and rubber grommets.

If necessary, the new wire should be fastened with insulating tape, plastic sealant, clamps or something else to prevent unnecessary noise in movement and chafing of the wire. At the same time, it is imperative to ensure that there is a distance of at least 10 mm between the brake pipes and wires, and a distance of at least 25 mm between the brake pipes and wires that oscillate with the engine or other parts of the car.

When drilling holes in the body, the edges of the holes must be cleaned, primed and painted. Chips that have flown out during drilling must be removed.

In all installation work with electrical wires, in order to avoid a short circuit, it is imperative to disconnect the negative cable from the battery and fix it to the side.

Attention: When disconnecting the wires from the battery, in some cases, data is erased from the engine and transmission diagnostic units, anti-lock brakes and some other electronic devices, such as a radio and clock. Specific instructions are given later in the section «Removing and installing the battery».

When additional electrical consumers are installed, in each case it must be checked whether the permissible load for the installed generator is not exceeded. If necessary, you need to install a more powerful generator.