Note: The arrows on the timing belts must point in the direction of rotation of the engine (those. clockwise).

When putting on the timing belts, you need to start with the crankshaft sprockets and put on the belts further in a counterclockwise direction, i.e. in the following sequence: crankshaft sprocket, camshaft sprocket or injection pump, tension sprocket. In this case, the weakened part of the toothed belt will fall on the spring-loaded tension roller.

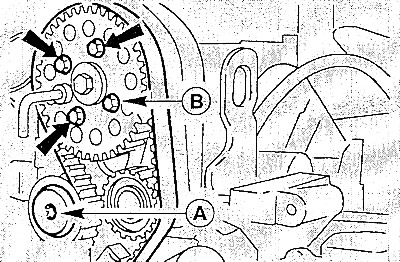

Attention: After putting on the toothed belt, the bolts of the toothed belt sprockets must be located in the middle of their elongated holes.

Loosen the mounting bolt (A) camshaft drive toothed belt tensioner pulley so that the tensioner lies against the belt under the action of the spring.

Tighten bolt (A) torque 50 Nm.

Tighten the mounting bolts (IN) camshaft sprockets with a torque of 10 Nm.

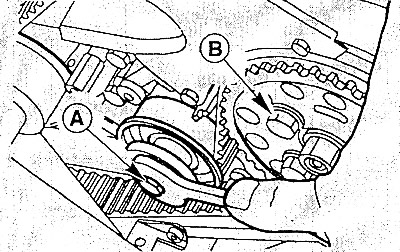

Loosen the mounting bolt (A) for the tension roller of the timing belt of the injection pump drive, so that the belt tensioner lies against the timing belt under the action of the spring.

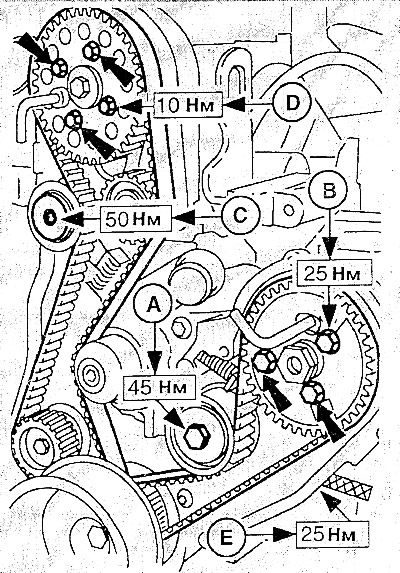

Tighten bolt (A) moment 45, Nm.

Tighten the mounting bolts (IN) injection pump sprockets with a torque of 25 Nm.

Remove all three dowel pins.

Rotate the crankshaft clockwise until the injection pump sprocket completes one full revolution. Finally, turn the crankshaft to TDC and insert the three dowel pins.

Loosen the bolts of the camshaft sprockets and injection pump.

Loosen the bolt (A) timing belt tensioner of the injection pump a quarter of a turn so that the belt tensioner is freely pressed against the timing belt.

Tighten bolt (A) tensioner of the toothed belt of the high-pressure fuel pump drive with a torque of 45 Nm. bolts (IN) Tighten injection pump sprockets to 25 Nm.

Loosen the bolt (WITH) camshaft timing belt tensioner a quarter of a turn so that the tensioner is freely pressed against the belt.

Tighten bolt (WITH) camshaft timing belt tensioner with a torque of 50 Nm. bolts (D) Tighten camshaft sprockets to 10 Nm.

Check again if the dowel pins are inserted correctly and the crankshaft rests against the dowel pin for TDC. Finally, remove all adjusting pins.

Screw the blind bolt into the cylinder block and tighten to 25 Nm.

Install the upper and lower toothed belt covers.

Install poly V-belt.

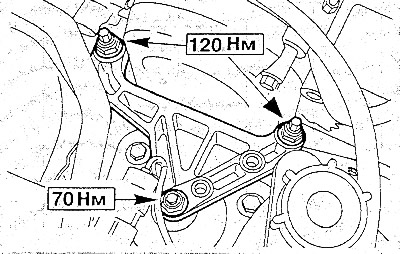

Install right engine mount and tighten new nuts. Tighten the nuts on the engine side to 120 Nm, on the body to 70 Nm.

Install the reinforcement holder on the right engine support and tighten the bolts to 50 Nm.

Unhook the lifting device or remove the jack from under the engine.

Connect the negative cable to the battery.

Set the clock and enter the required codes.