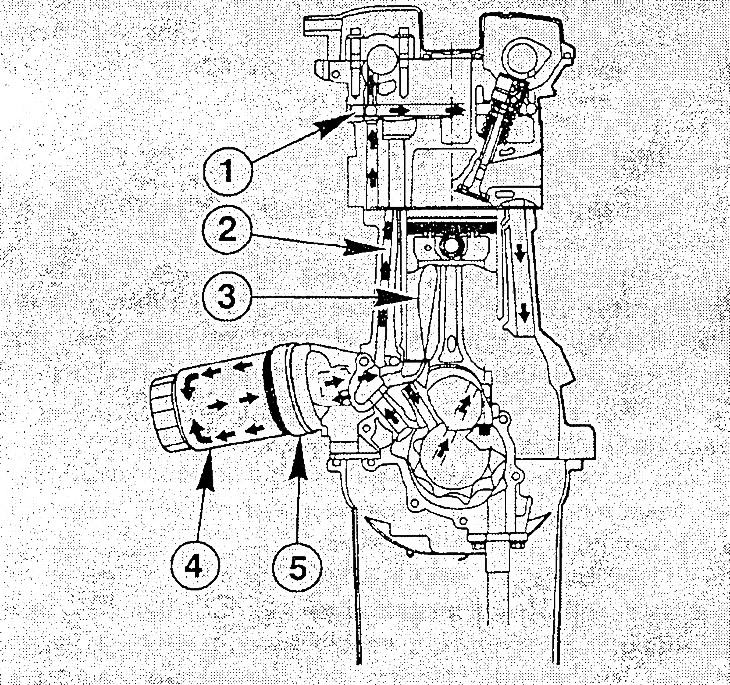

1. Oil dripping on the cylinder head; 2. Main oil line; 3. Oil injection for piston cooling; 4. Full flow oil filter; 5. Oil cooler.

The engines are equipped with a so-called closed pressure lubrication system. The oil pump draws engine oil from the oil pan through the strainer and delivers it to the oil filter. An oil pressure relief valve is located on the discharge side of the pump. If the oil pressure is too high, the valve opens and part of the oil flows back into the oil pan.

Through the middle part of the oil filter, the filtered oil enters directly into the main oil line. There is also a switch for the oil pressure warning lamp, which, using a warning lamp on the instrument panel, informs the driver of too low oil pressure. When the oil filter is clogged, the bypass valve directs unfiltered oil directly into the main oil line.

Channels for lubricating the crankshaft bearings depart from the main oil line. Through oblique holes in the crankshaft, oil is supplied to the connecting rod bearings. To cool the piston heads, oil is injected onto the pistons from below.

At the same time, oil is supplied through channels in the cylinder head and from there to the camshaft bearings and valve lifters.

On the 1.3L engine, the drive chain and camshaft sprocket are lubricated through a hole in the front channel.

Depending on the version, the oil is cooled in a heat exchanger on the oil filter flange, which is connected to the engine cooling system.