Attention:

- The engine has many parts made of aluminum alloys. These parts can be damaged if they come into contact with coolant based on alcohol or methanol. Do not use coolants based on alcohol or methanol. Use only coolants based on ethylene glycol.

- Use only soft (demineralized) water to prepare coolant from a concentrated solution. Water containing mineral salts reduces the cooling efficiency.

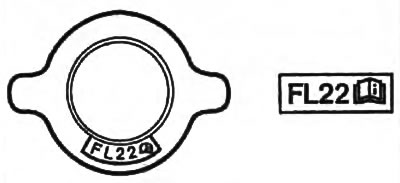

- If the filler cap is labeled "FL22", then for this cooling system, only the type of coolant should be used "FL22" (ratio: 55% antifreeze and 45% distilled water).

Examination

1. Check the quality of the coolant.

Attention: never open the radiator cap on a hot engine. Before opening the radiator cap, cover it with a thick cloth. When removing the radiator cap, initially turn it slightly until it first locks, after releasing pressure from the system, remove the cap completely.

A) Make sure there is no corrosion or deposits around the cap and radiator inlet.

b) Make sure that there are no oil impurities in the coolant.

2. Check the coolant level.

A) Make sure the coolant level is at the level of the filler neck.

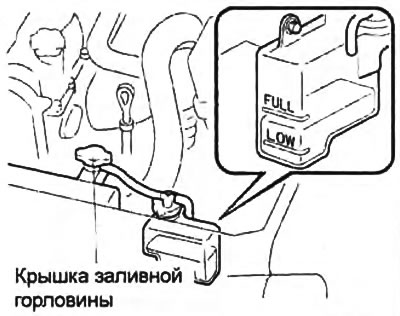

b) Check that the coolant level in the expansion tank on a cold engine is between the marks "FULL" And "LOW". If the level is below the mark "LOW", add coolant.

3. Check for coolant leakage.

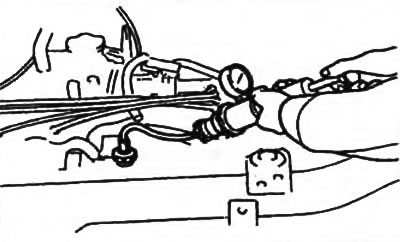

A) Using a special adapter, connect a standard tester for checking cooling systems to the coolant filler neck.

Note: pressurizing the cooling system above 122 kPa (1.25 kg/cm2) may damage parts of the cooling system and cause coolant leaks.

b) Pressurize the cooling system.

- Pressure - 122 kPa

V) Make sure the pressure doesn't drop. If the pressure drops, check the cooling system for coolant leaks.

Replacement

Attention:

- Changing the coolant or carrying out repairs that require draining the coolant must be carried out on a cold engine. Draining coolant on a hot engine can warp aluminum parts (including cylinder heads).

- Please note that below is the procedure for partial coolant replacement, as some of the coolant remains in the cylinder block.

1. Remove the expansion tank of the cooling system without disconnecting the hoses.

2. Remove the expansion tank cap and drain the coolant from the expansion tank into a suitable container.

3. Remove the filler cap.

4. Loosen the radiator drain plug and drain the coolant from the radiator into a suitable container through the radiator drain hole.

5. After the liquid has drained, tighten the radiator drain plug.

6. Pour coolant into the cooling system through the filler neck to the edges of the filler neck.

- The volume of the cooling system - 9.4 l

- Recommended coolant - FL22

Note: If necessary, flush the cooling system at this stage. Use distilled water.

7. Fill the coolant into the expansion tank up to the mark "FULL" on the wall of the tank.

8. Install the filler cap.

9. Start the engine and warm it up to normal operating temperature at idle.

Attention: if the temperature in the cooling system has risen above the norm, to prevent overheating, stop the engine and let it cool down. Repair the cooling system.

10. After warming up the engine, do the following:

A) Increase the engine speed to 2500 rpm for 5 minutes.

b) Increase engine speed to 3000 rpm for 5 seconds.

V) Carry out the procedure indicated in subparagraph "b" Five times.

11. Check the amount of coolant in the radiator.

If necessary, add coolant to the radiator and repeat the procedures from point "7".

Note: if the cooling system contains flushing fluid, then it is necessary to fill the system with the recommended coolant by following the procedures in steps 1-12. Do not forget that the replacement of the coolant is carried out on a cold engine.

12. Check the cooling system for leaks.

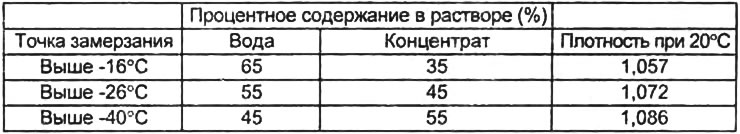

Table. The percentage of the coolant solution.