To reduce weight and improve thermal conductivity, the cylinder head is made of aluminum alloy. Gas distribution mechanism with two camshafts (UNOC) (one shaft to drive the intake valves and one to drive the exhaust valves). 4 valves per engine cylinder (two intake and two exhaust). By increasing the number of valves (WL engine has two valves per cylinder) an increase in the area of the flow section of the intake and exhaust channels was achieved, as a result of which an improvement in filling the cylinders with air and cleaning of the cylinders was achieved.

The geometry of the inlet ports is optimally selected to reduce inlet pumping losses.

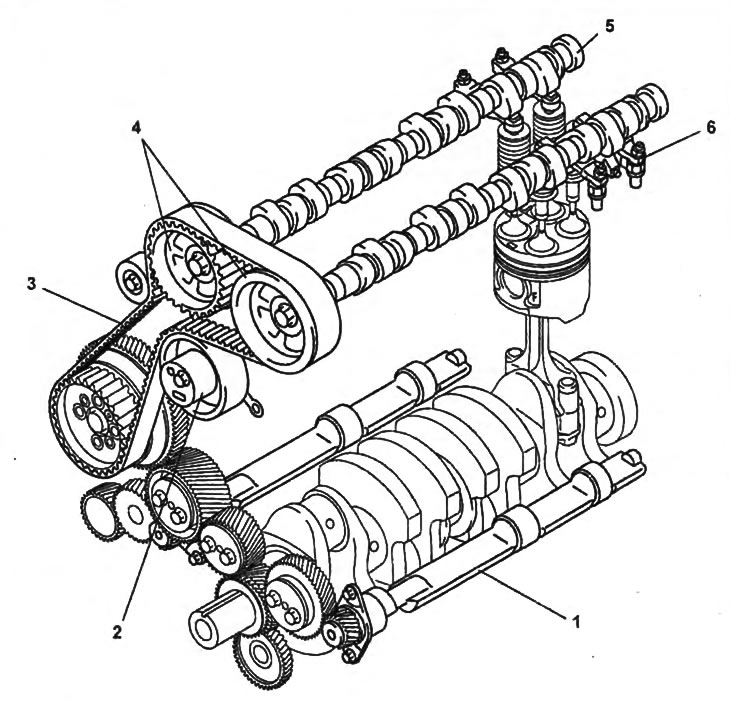

Gas distribution mechanism drive.

1 - balance shaft,

2 - timing belt tensioner,

3 - timing belt,

4 - camshaft pulleys,

5 - camshaft,

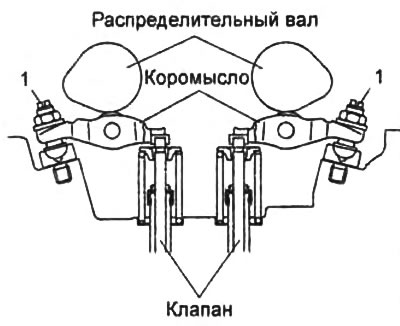

6 - rocker.

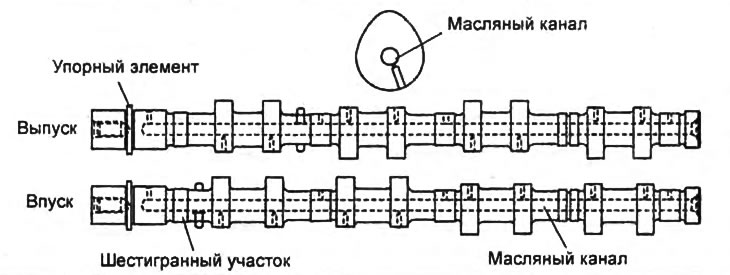

distribution shafts.

The valves are driven through rocker arms from the camshafts, which in turn are driven by the timing belt from the injection pump pulley. The thermal gap in the valves is adjusted by adjusting screws (1), located on the rocker arms.

The camshafts are made of cast iron. Camshafts are five-bearing. In each camshaft, one horizontal oil cable and several vertical ones are made, milking the supply of engine oil to the supports and cotton cams. In the front part, each camshaft has a thrust element that fixes the shaft from axial movement (see picture "Camshafts").

The cylinder block cooking gasket is made of laminated steel. Gaskets are produced in three size groups, differing in thickness.