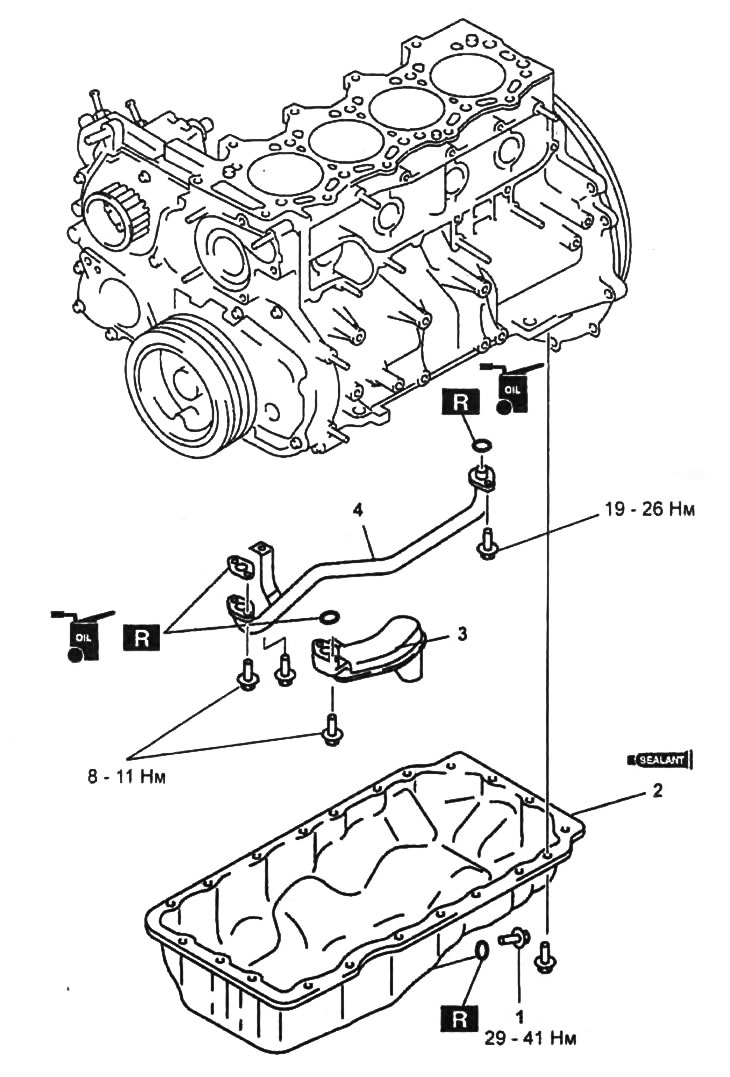

Oil Pan Removal Note

see chapter "Lubrication system" and drawing "Preliminary disassembly and assembly of the cylinder block (stage 1) ".

Note on removing the crankshaft pulley and injection pump pulley

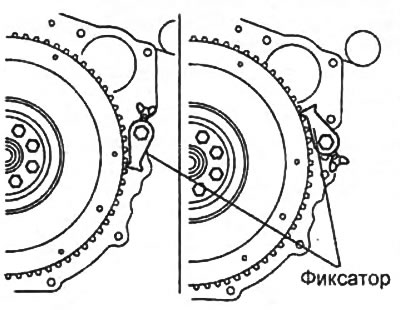

Lock the flywheel with the lock and remove the pulley.

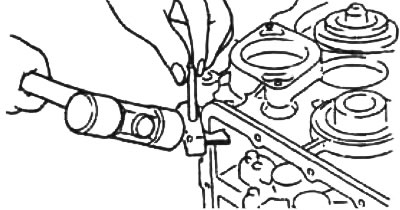

Note on removing the injection pump gear drive cover

1. Using a special separator, cut off the sealant and remove the cover of the high-pressure fuel pump drive gear mechanism.

2. Remove the gland of the cover of the gear drive mechanism of the injection pump using a slotted screwdriver wrapped in rags.

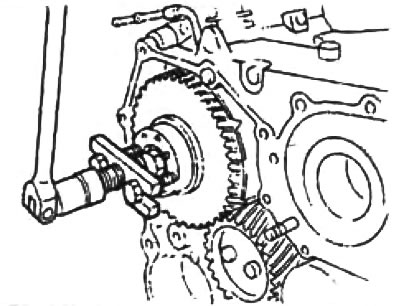

Note on removing the injection pump gear

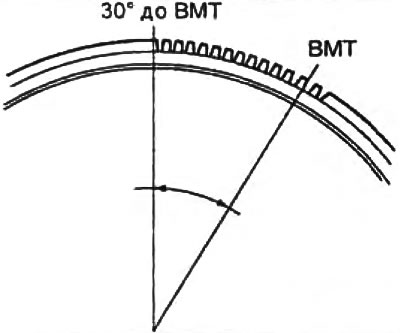

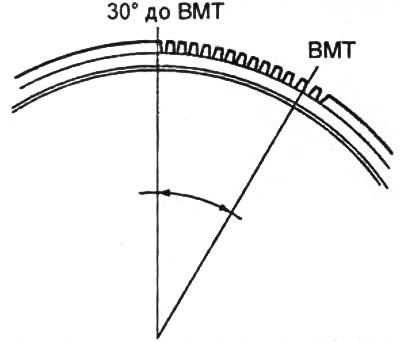

1. Turn the engine crankshaft clockwise so that the piston in the first cylinder is at TDC on the compression stroke.

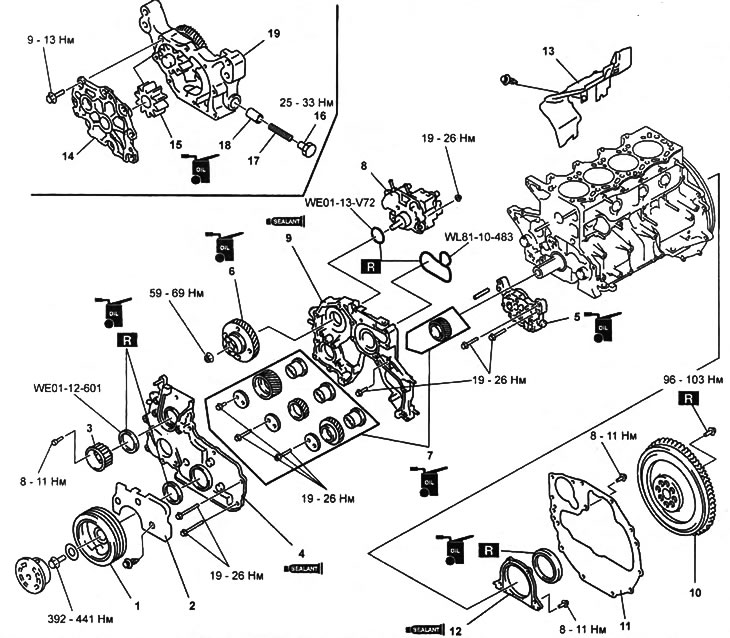

Preliminary disassembly and assembly of the cylinder block (stage 1).

1 - oil pan drain bolt,

2 - oil pan,

3 - oil receiver,

4 - oil tube.

2. Turn the flywheel and set the piston in the first cylinder 30°to TDC (13 teeth).

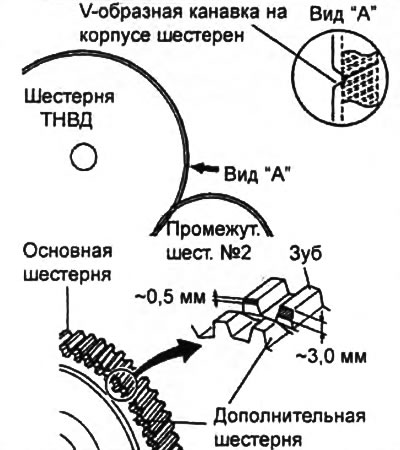

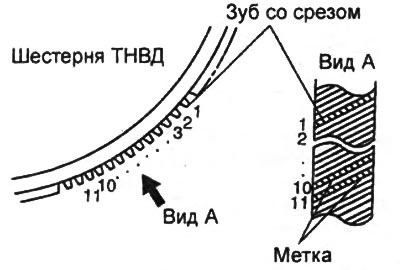

3. Make sure that the V-groove on the gear case is aligned with the high bevel gear tooth on the injection pump.

Note: If a heavily sheared tooth is difficult to locate, move the injection pump gear back and forth on the key and locate the tooth.

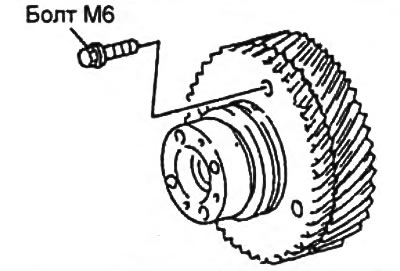

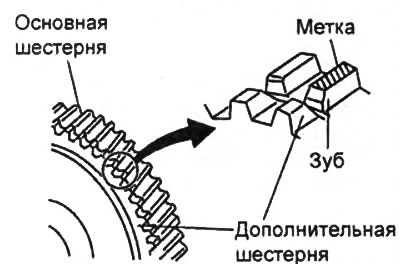

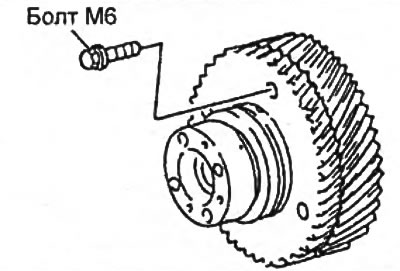

4. Fix the additional gear of the injection pump on the main gear by screwing the bolt No. 6X1.0 with a thread length of 16 mm into the gears.

Caution: When removing the injection pump gear, make sure that the secondary gear is securely bolted to the main gear, otherwise the secondary gear may turn under the force of the spring, which may cause injury, as well as cause the secondary gear to shift from the desired position, resulting in the gear The injection pump will not properly engage with idle gear #2.

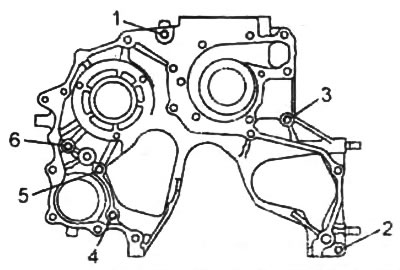

Preliminary disassembly and assembly of the cylinder block (stage 2).

1 - crankshaft pulley,

2, 13 - sealing cover,

3 - a gear pulley of a high-pressure fuel pump,

4 - front cover of the gear mechanism,

5 - oil pump housing assembly,

6 - high pressure fuel pump drive gear,

7 - elements of the gear drive mechanism of the injection pump,

8 - injection pump,

9 - gear mechanism housing,

10 - flywheel,

11 - back plate,

12 - crankshaft rear oil seal holder,

14 - oil pump cover,

15 - driven rotor,

16 - plug,

17 - spring,

18 - pressure reducing valve,

19 - oil pump housing.

5. Turn away a nut of fastening of a gear wheel of TNVD, having fixed a flywheel from rotation by special adaptation.

6. Using a puller, remove the injection pump gear.

Note on removing the housing of the gear mechanism of the injection pump drive

Using a hammer and a special separator, cut off the sealant and remove the housing of the injection pump drive mechanism.

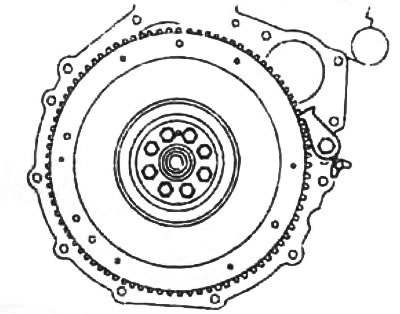

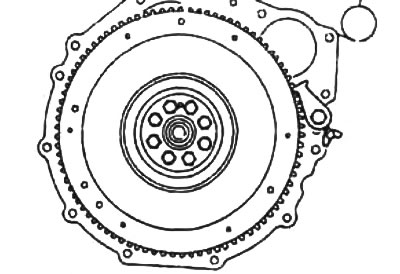

Flywheel Removal Note

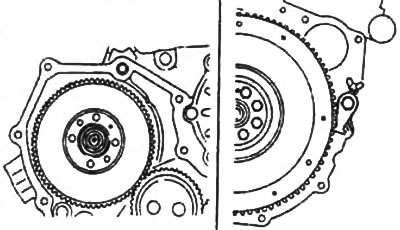

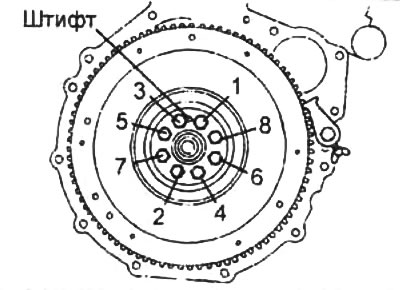

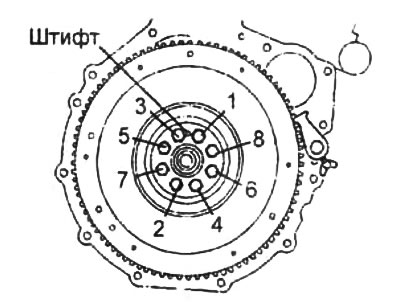

Fix the flywheel with a latch and remove it by unscrewing the mounting bolts in the sequence shown in the figure.

Note on removing the crankshaft rear oil seal

With a screwdriver wrapped in cloth. remove the seal.

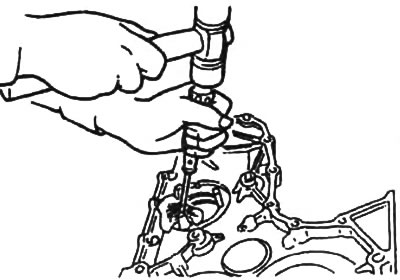

Oil Pump Cover Installation Note

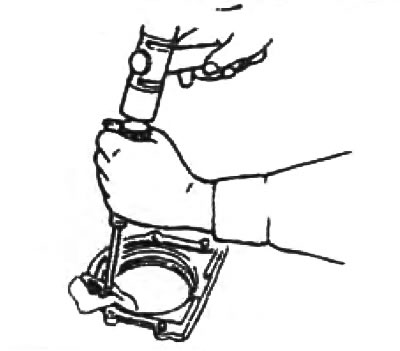

Tighten the oil pump cover bolts in several passes in the sequence shown in the figure.

- Tightening torque - 9-13 Nm

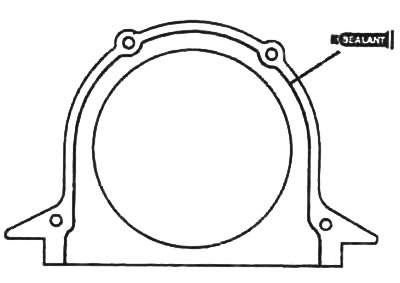

Note on installing the crankshaft rear oil seal holder

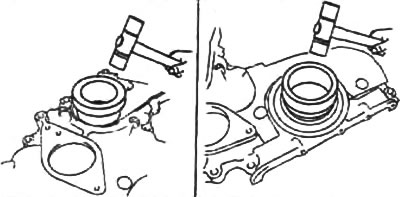

1. Apply a coat of engine oil to the lip of the oil seal.

2. Using a mandrel of suitable diameter and a hammer, press the oil seal into the rear oil seal holder.

3. Apply silicone sealant to the contact surface of the crankshaft rear oil seal holder and install the holder with the oil seal on the cylinder block.

- Sealant thickness - 2-3 mm

Note: Parts must be installed within the time specified in the instructions for use of the sealant. Otherwise, the sealant must be removed and reapplied.

4. Apply a bead of sealant to the contact surface of the rear oil seal holder as shown.

- Sealant thickness - 2-3 mm

Note: Parts must be installed within the time specified in the instructions for use of the sealant. Otherwise, the sealant must be removed and reapplied.

5. Install the back plate.

Flywheel installation note

1. Fix a cranked shaft by means of a clamp.

2. Tighten the flywheel mounting bolts in the sequence shown in the figure.

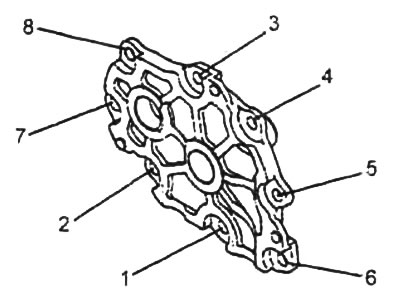

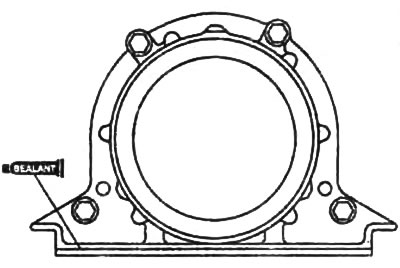

Note on installing the housing of the gear mechanism of the injection pump drive

1. Install a new sealing ring in the injection pump drive mechanism housing.

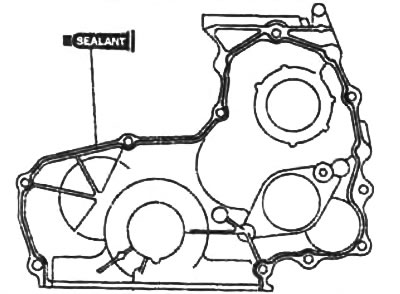

2 Apply silicone sealant to the surface of the injection pump drive mechanism housing in the places indicated in the figure.

Note: Make sure no sealant gets on the o-ring.

- Sealant thickness - 2-3 mm

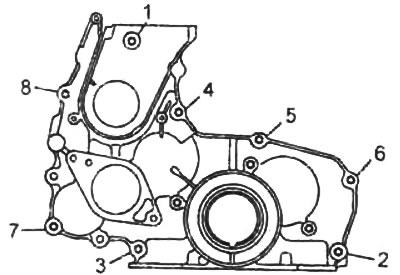

3. Tighten the bolts for fastening the housing of the gear mechanism of the injection pump drive in two or three passes in the sequence shown in the figure.

Note on the installation of elements of the gear mechanism of the injection pump drive

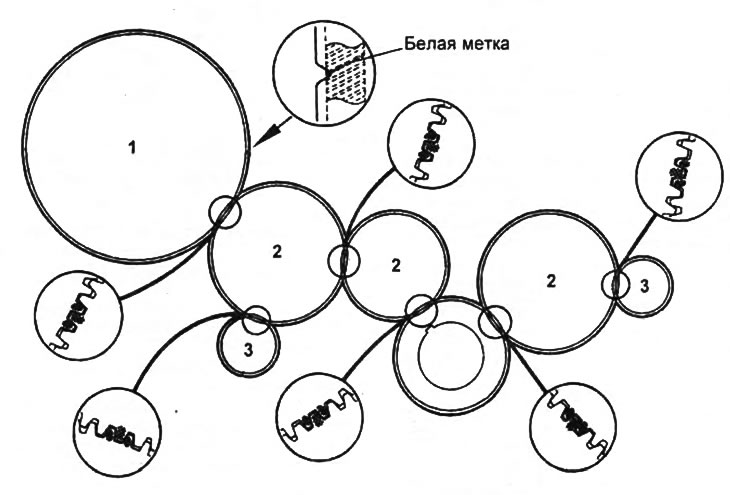

1. Put a mark on the tooth of the injection pump gear, which has a large oblique cut.

2. Mark the 10th and 11th teeth of the injection pump main gear, moving clockwise from the large beveled tooth.

3. Check that the 10th and 11th teeth of the main gear of the injection pump are aligned with the teeth of the secondary gear, and mark the teeth of the secondary gear.

4. Turn the engine crankshaft clockwise so that the piston in the first cylinder is at TDC on the compression stroke.

5. Turn the flywheel and set the piston in the first cylinder 30°to TDC (13 teeth).

6. Align the marks on the gears of the injection pump drive mechanism with the alignment marks, as shown in the figure "Combination of labels of the gear mechanism of the injection pump drive".

7. Remove the bolt securing the additional gear to the main gear of the injection pump.

8. Secure the flywheel with the lock.

9. Tighten the bolts for fastening the gears of the injection pump drive mechanism.

Alignment of the marks of the gear drive mechanism of the injection pump.

1 - high pressure fuel pump gear,

2 - intermediate gear,

3 - balancer shaft gear.

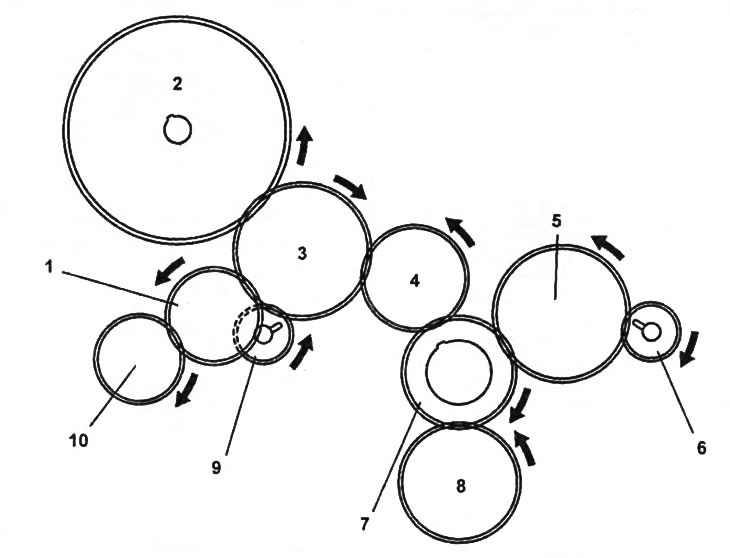

Drive gears.

1 - vacuum pump gear,

2 - high pressure fuel pump gear,

3 - intermediate gear No. 2,

4 - intermediate gear No. 1,

5 - intermediate gear No. 3,

6, 9 - balance shaft gear,

7 - crankshaft gear,

8 - oil pump gear,

10 - gear wheel of the power steering pump.

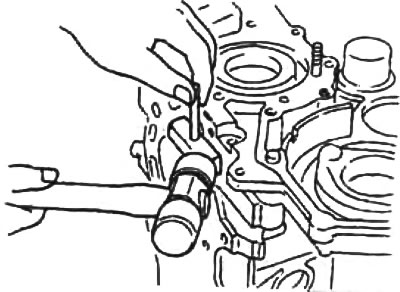

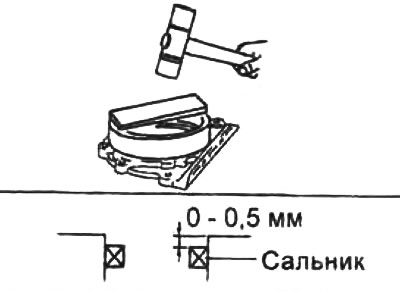

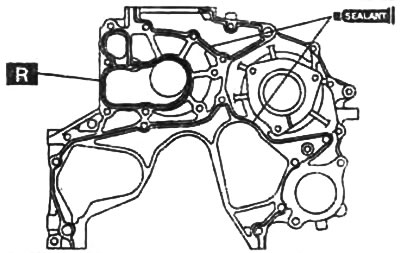

Note on installing the injection pump gear drive cover

1. Apply a coat of engine oil to the lip of the oil seal.

2. Press in the gland of the cover of the gear mechanism of the injection pump drive using a mandrel of a suitable diameter and a hammer.

- Depth of pressing - 0-0.4 mm

3. Apply silicone sealant to the contact surfaces of the high pressure fuel pump drive gear mechanism cover in the places indicated in the figure.

- Sealant thickness - 2-3 mm

Note: Parts must be installed within the time specified in the instructions for use of the sealant. Otherwise, the sealant must be removed and reapplied.

4. Tighten the bolts securing the cover of the gear mechanism of the injection pump drive in two or three passes in the sequence shown in the figure.

Note on installing the crankshaft pulley and injection pump pulley

Lock the flywheel with the lock and install the pulley.