Removal and installation

1. Disconnect a wire from the negative plug of the storage battery.

2. Remove the front side trim.

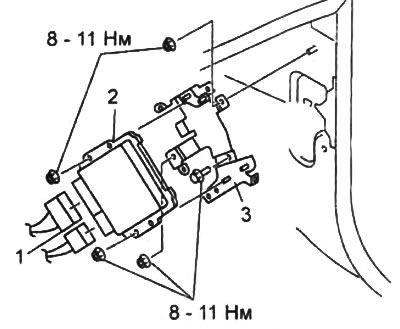

3. Remove the parts in the order they are numbered in the figure.

1 - connectors,

2 - engine control unit,

3 - control unit bracket.

4. Installation of parts during assembly is carried out in the reverse order of removal.

5. If the engine control unit was replaced, then perform the following procedures:

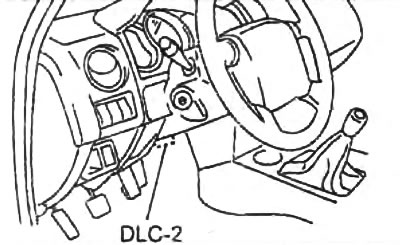

A) Connect the scanner to the DLC2 diagnostic socket.

b) From the scanner menu, select "Module Programming", Further "Programmable Module Installation", Further "PCM" and follow the instructions on the scanner display

V) Carry out the procedure for programming the immobilizer keys.

G) Erase the memory of the control unit (see relevant subsection below).

d) Follow the procedures in section "After repair work". Remove air from the fuel system.

e) Start the engine.

and) Set the ignition switch to position "OFF".

h) Set the ignition switch to position "0N" (engine off).

And) Diagnose and check for DTCs that may occur with the engine off (Key on engine off test).

To) Set the ignition switch to position "OFF".

l) Wait 5 seconds

m) Start the engine

n) Diagnose and check for DTCs that may occur with the engine running (Key on engine running test),

O) Set the ignition switch to position "OFF".

Registration of injector identification codes

Attention:

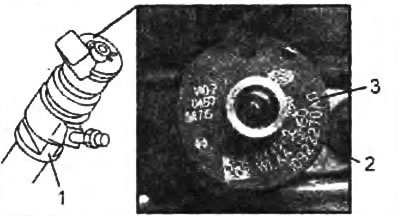

- After replacing the engine control unit or injectors, it is necessary to program the registration code of the injectors into the memory of the control unit, otherwise the indicator will light "Check Engine" and fault codes P1675 and P1676 are displayed.

- The injector identification code is printed on the injector body.

Note:

- Injector identification code (2) is an eight-digit digital code printed on the nozzle body (1). This code carries the encrypted characteristics of the injector (varying depending on the mechanical characteristics of each nozzle) and is used by the engine control unit to calculate the optimal amount of fuel injected by the injector. Registration of this code allows the control unit to optimize the amount of fuel injected by the injector and improve fuel efficiency.

- The last two characters of the code "JSC" (3) there is no need to memorize the control unit, these symbols indicate that the nozzle is installed on the WL-C engine.

1. Connect the scanner to the diagnostic connector DLC2.

2. From the scanner menu, select "Module programming", Further "Programmable parameters", Further "injector correction factor" and follow the instructions on the scanner display.

3. Enter injector identification codes for each cylinder.

After entering the ID codes, check for diagnostic trouble codes.

Erasing the memory of the control unit

1. Connect the scanner to the diagnostic connector DLC2.

2. From the scanner menu, select "Powertrain", Further "Data Reset", Further "PCM" and follow the instructions on the scanner display.

3. Check for diagnostic trouble codes. Make repairs if necessary.

Setting the correction parameters of the mass air flow sensor

Attention: this procedure should be performed after replacing the mass air flow sensor / sensor No. 2 intake air temperature or every 12 months.

Using a scanner

1. Initial conditions:

A) The engine is warmed up to normal operating temperature.

b) All electrical consumers and air conditioning are off.

V) Gear lever in neutral position.

G) Accelerator pedal fully released.

d) There are no diagnostic trouble codes.

2. Connect the scanner to the diagnostic connector DLC2.

3. From the scanner menu, select "Powertrain", Further "Engine Checks", Further "Learning", select "MAF Correction" and follow the instructions on the scanner display.

Without using a scanner

Note: during the procedure, the indicator "GLOW" should burn. At the end of the procedure, the indicator "GLOW" should flash five times.

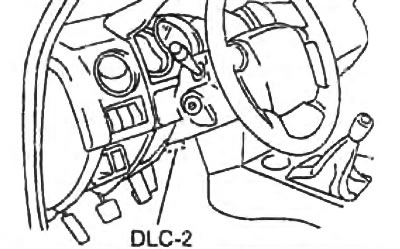

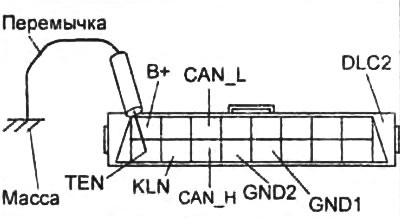

To perform this procedure without using a scanner, close the output five times within five seconds "TEN" DLC2 diagnostic connector to ground, using a jumper.

Erasing correction parameters of the mass air flow sensor

1. Connect the scanner to the diagnostic connector DLC2.

2. From the scanner menu, select "Powertrain", Further "Data Reset", Further "MAF Sensor" and follow the instructions on the scanner display.

3. Check for diagnostic trouble codes. Make repairs if necessary.