Attention:

- Cover all adjacent parts with rags to prevent fuel from getting on them.

- After removing the high pressure fuel pipes, keep them free of dirt and foreign material. When installing fuel pipes, tighten their fastening nuts to the specified torque.

- Remove and install parts strictly in the sequence below to avoid fuel leakage.

- The number of times that high pressure fuel lines can be reused without loss of reliability is limited. It is only allowed to re-install the old high-pressure pipes five times after they have been removed. After the sixth removal of the high pressure tubes, they must be replaced.

- When connecting the fuel hoses, refer to the figure "Location of fuel system components in the engine compartment".

- If the injector was replaced, then the identification code of the new injector should be programmed into the memory of the engine control unit.

1. Disconnect a wire from the negative plug of the storage battery.

2. Follow the procedures in section "Before repair work".

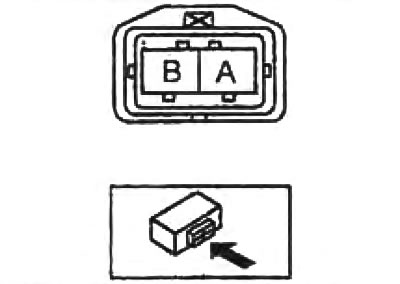

3. Disconnect the connectors of the following items:

- Camshaft position sensor.

- Coolant temperature sensor.

- Fuel accumulator pressure sensor.

- Nozzles.

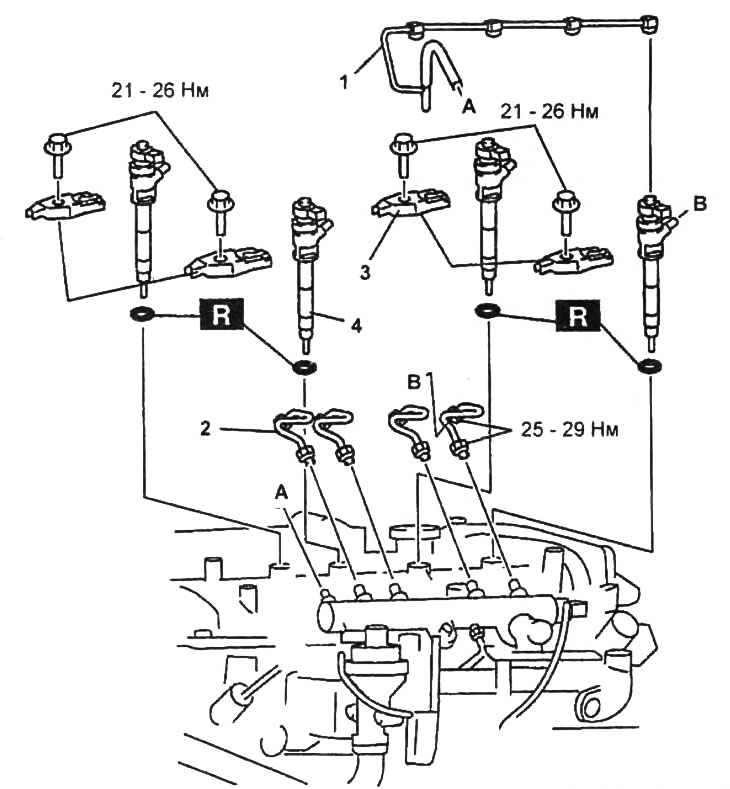

4. Remove the parts in the numbering sequence shown in the assembly drawing "Removal and installation of nozzles".

5. Installation of details is made in sequence, return to removal.

6. Follow the procedures in section "After the repair work".

Injector test

1. Disconnect a wire from the negative plug of the storage battery.

2. Disconnect the connector from the injector and, using an ohmmeter, check the resistance between the injector leads (at 20°С).

- Resistance - 0.225 Ohm

If the resistance between the injector terminals is different from the specified value, replace the injector.

Removal and installation of nozzles.

1 - fuel return hose,

2 - high pressure fuel pipes,

3 - nozzle holder,

4 - nozzle.