Removal and installation

Caution: Repairing a fuel tank that has not been properly steam cleaned can be hazardous. Tank explosion or fire can cause serious injury or death.

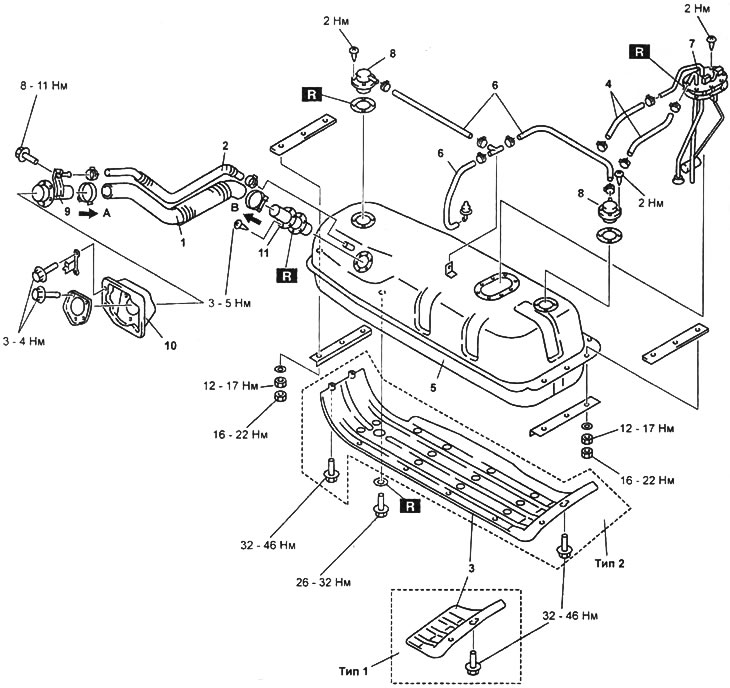

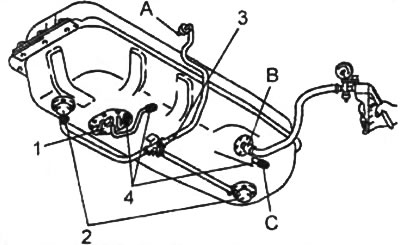

Note: see picture "Removal and installation of the fuel tank".

1. Park the vehicle on a level, level surface.

2. Disconnect a wire from the negative plug of the storage battery.

3. Follow the procedures described in section "Before repair work".

4. Remove the drain plug and drain the fuel into a suitable container.

5. Remove the tailgate.

6. Remove the parts in the order they are numbered in the figure "Removal and installation of the fuel tank".

7. Installation of parts during assembly is carried out in the reverse order of removal.

8. Follow the procedures described in section "After repair work".

Note on installing the connecting hose of the fuel filler tube

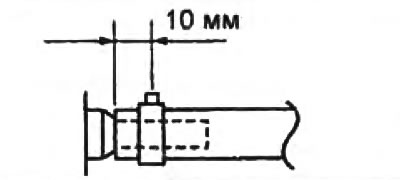

1. Slide the hose until it touches the side of the fuel tank, then insert the tube into the hose for a distance of 35 mm.

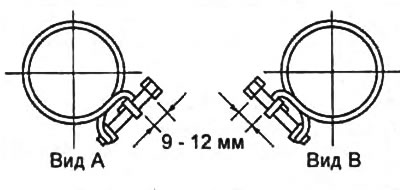

2. Install the clamps as shown.

Vent Hose, Fuel Hose, and Evaporative Emission Hose Installation Note

When installing, it is necessary to push the hoses over the pipes by a distance of at least 25 mm.

Install the clamps as shown.

Examination

Note: the test is carried out for the fuel tank, the safety valve of which is removed.

1. Follow the procedures described in the section "Before repair work".

2. Disconnect a wire from the negative plug of the storage battery.

3. Remove the fuel tank.

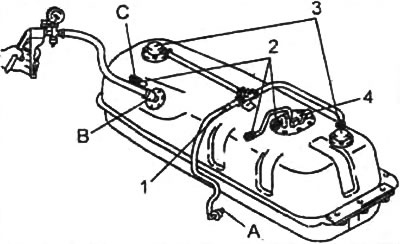

4. Install a plug in the fuel tube port of the fuel level sensor.

5. Install the plug in the port "WITH".

6. Connect a hand pump to the port "IN".

1 - valve (2 way),

2 - plug,

3 - safety valve,

4 - fuel level sensor.

7. Place the fuel tank on a level surface.

8. Pressurize 5 - 6 kPa (38 - 45 mmHg Art.).

9. Make sure air is coming out of the fitting "A".

If air does not come out of the fitting "A", replace both fuel tank relief valves and three fuel hoses.

10. Create a vacuum of 5-6 kPa (38-45 mmHg Art.) and make sure air is being sucked into the fuel tank.

Removal and installation of the fuel tank.

1 - connecting hose of the fuel filler neck,

2 - ventilation hose,

3 - bottom protection,

4 - fuel hoses,

5 - fuel tank,

6 - hose of the fuel vapor recovery system,

7 - fuel level sensor,

8 - valve,

9 - fuel filler tube,

10 - anther,

11 - connecting tube.

If air is not drawn into the fuel tank. replace both fuel tank relief valves and three fuel hoses.

11. Turn over the fuel tank. Connect a hand pump to the port "IN", as it shown on the picture.

1 - fuel level sensor,

2 - safety valve,

3 - valve (2 way),

4 - plug.

12. Create an overpressure of 5-6 kPa (38-45 mmHg Art.).

13. Make sure air is not escaping from the fitting "A".

If air comes out of the fitting "A", replace both fuel tank relief valves and three fuel hoses.