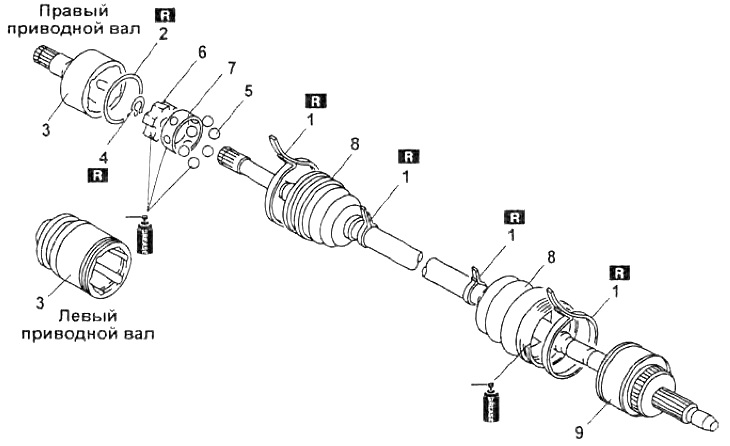

Drive shaft.

1 - collar,

2 - thrust ring,

3 - outer cage of the inner hinge,

4 - retaining ring,

5 - balls,

6 - inner race of the inner hinge,

7 - separator,

8 - cover,

9 - outer hinge.

2. Assembly is made in the reverse order of disassembly.

Note:

- Do not disassemble the outer hinge.

- Remove hinge covers only when necessary.

Disassembly Notes

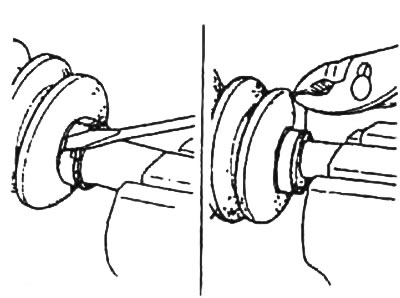

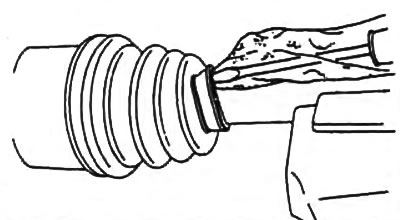

1. Remove the hinge boot clamp.

A) Use a screwdriver to pry off the anther collar lock.

b) Pull the tie off the end of the tape.

V) Remove the grease in the boot.

2. Remove the thrust ring.

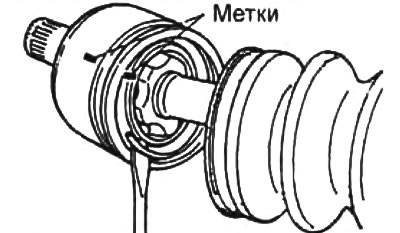

A) Mark the outer race of the joint and the drive shaft as shown in the illustration.

Attention: use only paint for marking, do not mark with a core.

b) Remove the thrust ring.

3. Remove the retaining ring.

A) Mark the outer race of the joint and the drive shaft as shown in the illustration.

Attention: use only paint for marking, do not mark with a core.

b) Remove the retaining ring using a puller.

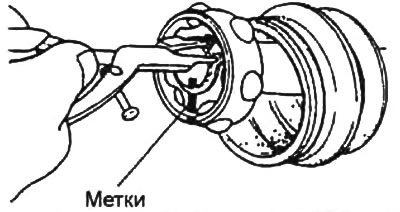

4. Remove separator and balls.

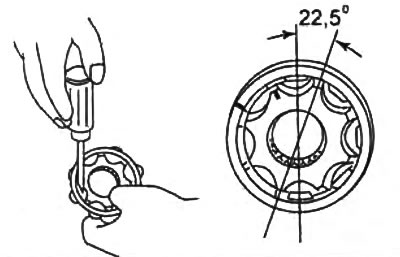

A) Mark the inner race and cage.

Attention: use only paint for marking, do not mark with a core.

b) Rotate the cage approximately 22.5°, remove the balls from the inner race and remove the cage.

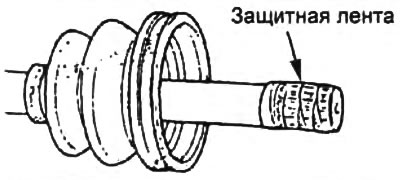

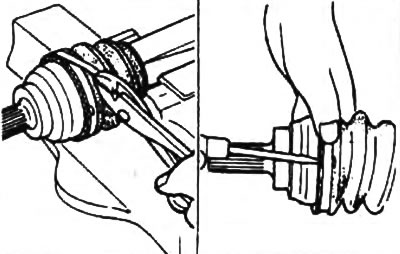

5. Wrap the protective tape around the splines of the drive shaft and remove the cover.

Note: Disassemble the outer hinge only if necessary.

Assembly notes

1. Install the outer hinge boot.

A) Fill the outer joint boot with grease.

- Amount of lubricant - 110-130 g

Caution: Do not allow foreign material to enter boot and grease.

Note:

- Covers of internal and external hinges have different sizes.

- Use the grease supplied in the repair kit.

b) Without removing the protective tape wound during removal, install the boot on the drive shaft.

V) Remove the protective tape.

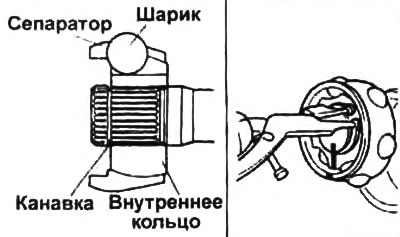

2. Install cage, inner race, balls, and circlip.

A) Align the marks and install the balls, inner race and cage, orienting the cage as shown.

Note: install the separator with protruding edges towards the groove of the retaining ring. If the separator is installed incorrectly, the drive shaft may be disconnected.

b) Install a new retaining ring.

3. Install the outer race of the inner joint.

A) Align the marks on the outer race of the joint and the drive shaft.

b) Install a new thrust ring.

4. Install outer race and thrust washer.

Note: Use only the special lubricant sold with the case.

A) Fill the boot and outer race of the inner joint with special grease.

- Amount of lubricant - 115 - 135 g

b) Install the cover.

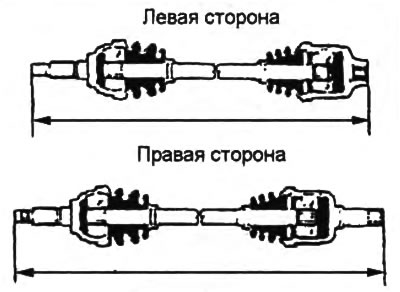

V) Install drive shafts.

Drive shaft length:

- left - 507.8 - 517.8 mm

- right - 596.7 - 606.7 mm

G) Release the air from the case with a screwdriver wrapped in cloth.

5. Establish a collar of a cover of the internal hinge.

Note:

- Always use only new clamps.

- The clamp must be twisted in the direction opposite to the rotation of the drive shaft when moving forward.

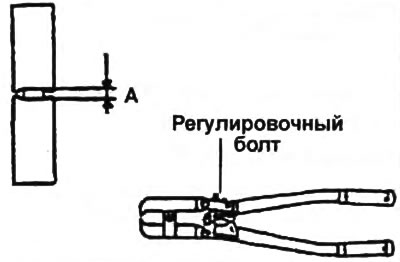

A) Bend the clamp back and tighten with pliers.

b) Clamp the end of the clamp by bending the retaining clip.

6. Establish a collar of a cover of the external hinge.

A) Rotate the adjusting bolt of the special tool for installing clamps, set the gap "A" between the jaws of the special device.

- Gap "A" - 2.9 mm

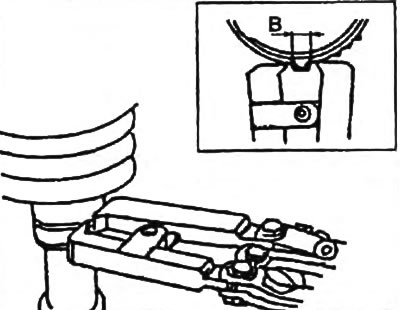

b) Squeeze the small collar of the anther with the special tool. Make sure the gap "IN" corresponds to the norm.

Note:

- If the gap "IN" more than normal, reduce the gap '"A" between the jaws of the special tool and squeeze the clamp again.

- If the gap "IN" less than normal: replace the clamp with a new one, increase the gap "A" between the jaws of the special tool and squeeze a new clamp.

- Gap "IN" - 2.6 - 2.8 mm

V) Make sure that the clamp band does not protrude from the mounting groove of the boot.

Note: if the clamp protrudes beyond the groove, replace the clamp and repeat the steps described in paragraphs "b" And "V".

G) Fill the case with special grease.

d) By turning the adjusting screw of the special tool, adjust the gap "A".

- Gap "A" - 3.2 mm

X) Using the special tool, tighten the large collar of the outer hinge cover.

and) Make sure the gap "IN" corresponds to the norm.

Note:

- If the gap "IN" more than normal, reduce clearance "A" between the jaws of the special tool and squeeze the clamp again.

- If the gap "IN" less than normal, replace the clamp with a new one, increase the gap "A" between the jaws of the special tool and squeeze a new clamp.

- Gap "IN" - 2.4 - 2.6 mm

h) Make sure that the clamp band does not protrude from the mounting groove of the boot.

Note: if the clamp protrudes beyond the groove, replace the clamp and repeat the steps described in paragraphs "e" And "and".