Assembly notes

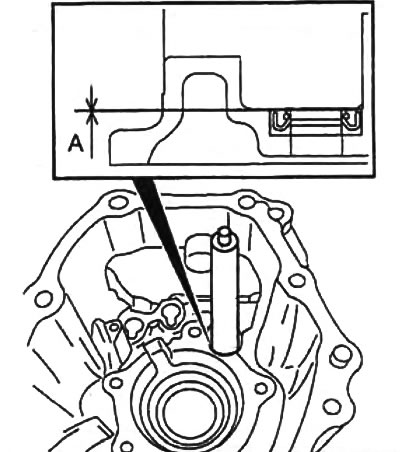

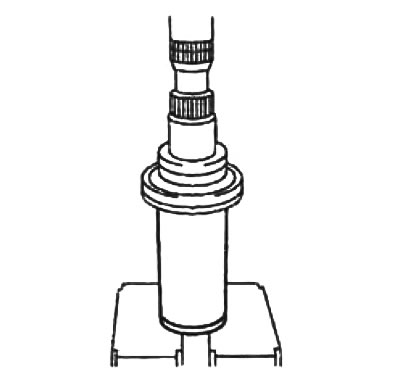

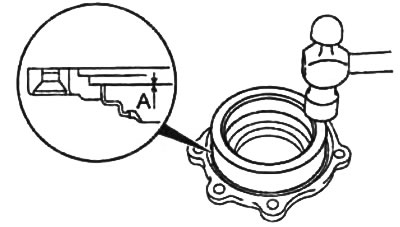

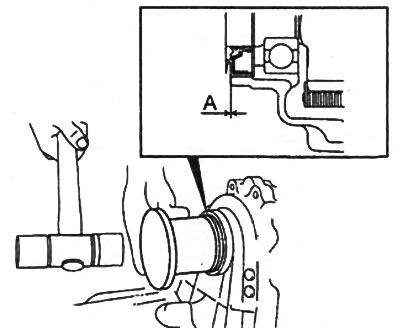

1. Control arm oil seal.

A) Apply grease to the sealing lip of the stuffing box.

b) Using a mandrel and a hammer, install the oil seal as shown in the illustration.

- Installation depth "A" - 0 mm

Note: Do not confuse the gland position when installing.

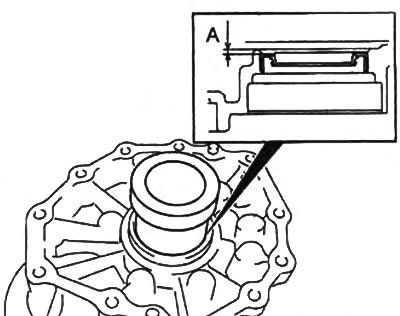

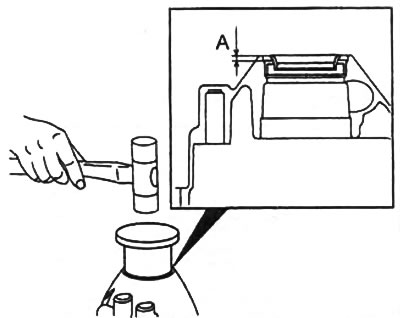

2. Input shaft seal.

A) Apply grease to the sealing lip of the stuffing box.

b) Using a mandrel and a hammer, install the oil seal as shown in the illustration.

- Installation depth "A" - 2.4-3.0 mm

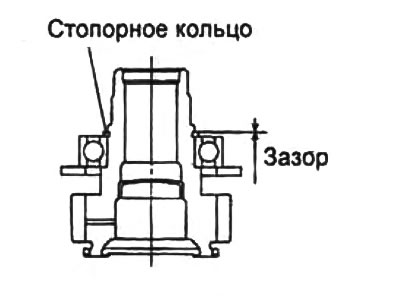

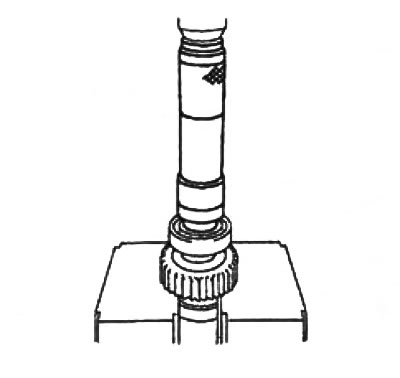

3. Input shaft bearing.

A) Using drifts and a press, install the bearing.

b) Install retaining ring.

V) Measure the gap shown in the figure.

- Gap - 0 - 0.15 mm

If the clearance is not correct, select the thickness of the retaining ring.

Note: Retaining rings are available in 2.60 thickness; 2.67 and 2.74 mm.

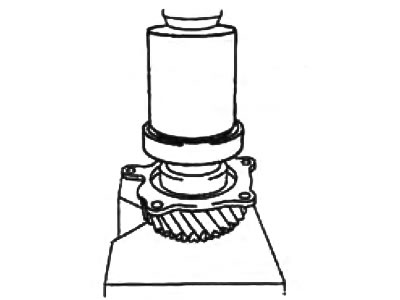

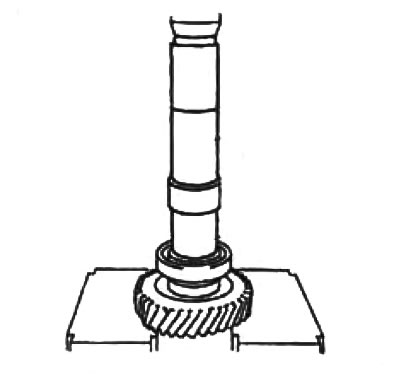

4. Front and rear intermediate shaft bearings.

Using a press and mandrels, install the bearings on the intermediate shaft.

front bearing.

Rear bearing.

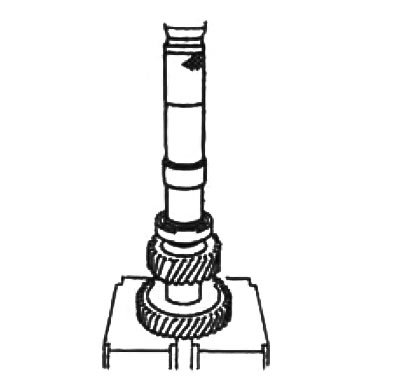

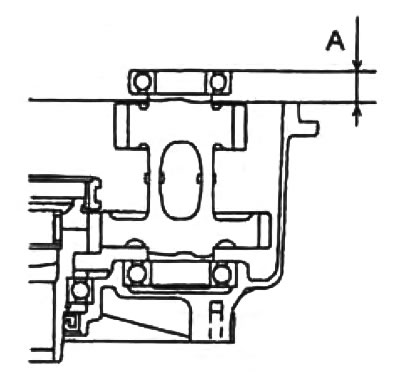

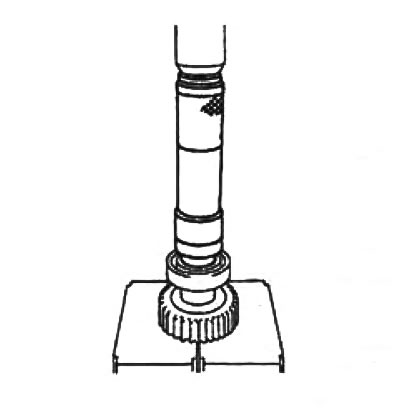

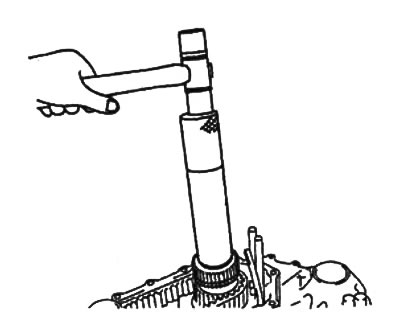

5. Intermediate shaft.

A) Install the intermediate shaft into the front housing.

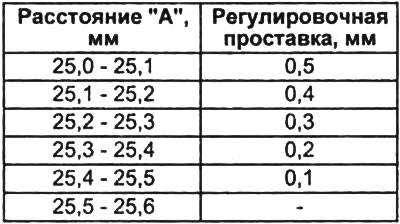

b) measure distance "A", shown in the figure.

V) Based on the measured distance. "A" select the adjusting spacer according to the table.

G) Install the adjuster.

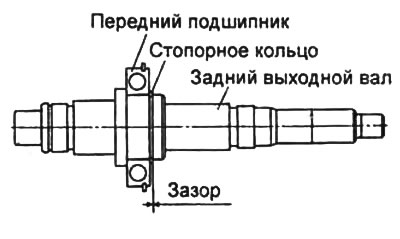

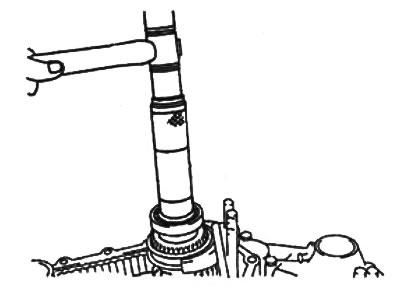

6. Front bearing rear output shaft and rear output shaft.

A) Using a drift and a press, install the front bearing onto the rear output shaft.

b) Measure the clearance between the circlip and the groove in the rear output shaft.

- Gap - 0-0.15 mm

V) Install the rear output shaft into the center housing. Drive the shaft into the housing with a plastic mallet.

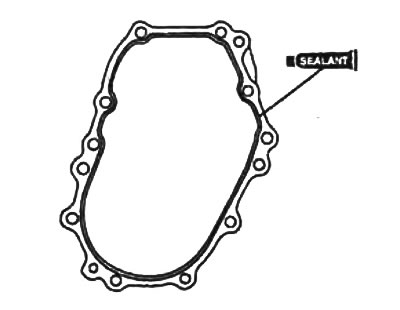

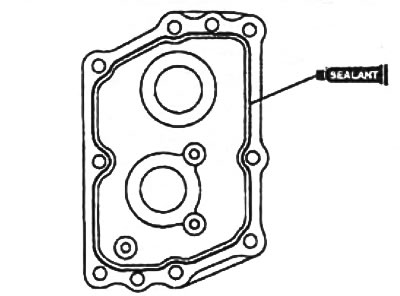

7. Central building.

A) Apply sealant to the contact surface of the center housing as shown.

b) Install the center housing and tighten the bolts.

- Bolt length - 43 mm

- Tightening torque - 11 - 48 Nm

8. Oil drain.

Install the oil drain on the center body. Align the grooves when installing.

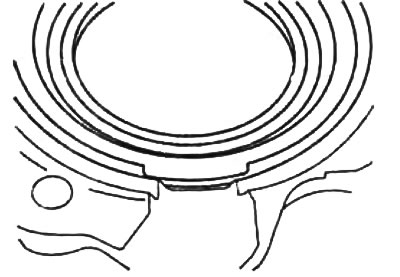

9. Oil separator.

A) Align the groove of the oil catcher.

b) Apply oil to the sealing lip.

V) Using a drift and a hammer, install the oil separator as shown in the figure.

- Installation depth "A" - 0 mm

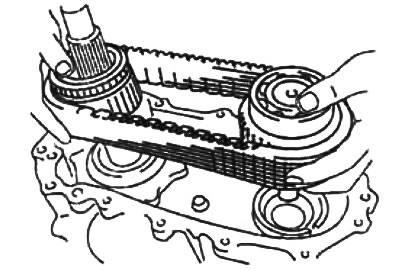

10. Chain, front output shaft and drive sprocket.

A) Install the chain, front output shaft and sprocket assembly into the housing. Drive the front output shaft into the housing with a plastic mallet.

b) Rotate the rear output shaft to install the needle bearing on the drive sprocket.

11. Front and rear bearings of the front output shaft.

Using drifts and a hammer, install the bearing onto the front output shaft.

front bearing.

Rear bearing.

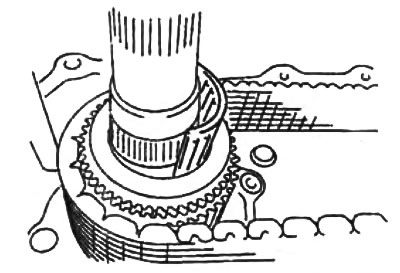

12. All wheel drive hub.

Using drifts and a hammer, install the 4WD hub.

13. Rear bearing of the rear output shaft.

Using drifts and a hammer, install the rear bearing onto the rear output shaft.

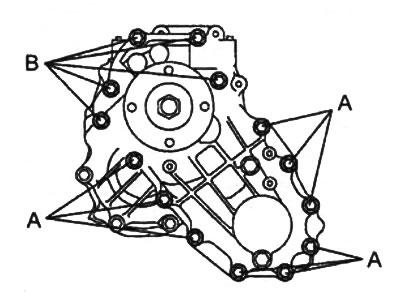

14. Rear case.

A) Apply sealant to the contact surface of the rear housing as shown in the illustration.

b) Install the rear housing and tighten the bolts.

Bolt length:

- bolts "A" - 58 mm

- bolts "IN" - 113 mm

Tightening torque - 41 - 48 Nm

15. Front output shaft seal.

A) Apply grease to the sealing lip of the new oil seal.

b) Using a mandrel and a hammer, install the oil seal as shown in the illustration.

- Installation depth "A" - 0 mm

16. Rear output shaft seal.

A) Apply grease to the sealing lip of the new oil seal.

b) Using a mandrel and a hammer, install the oil seal as shown in the illustration.

- Installation depth "A" - 6.7 - 7.3 mm

17. Cover of the control mechanism.

A) Apply sealant to the contact surface of the control mechanism cover as shown in the figure.

b) Install the cover and tighten the bolts.

- Tightening torque - 16 - 33 Nm